About Eight Head Liquid Filling Machine Controller

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

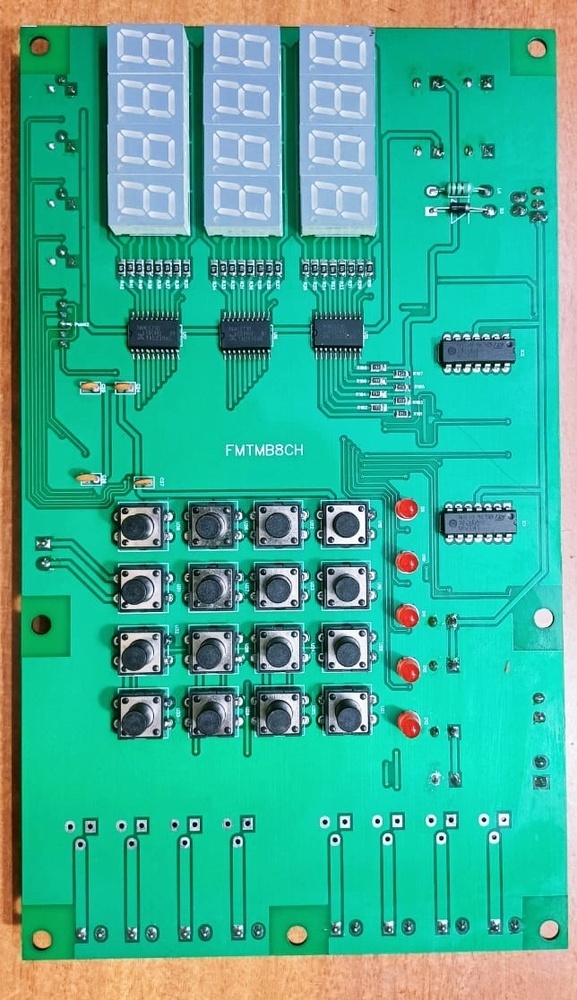

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Precision Control for Diverse Filling NeedsEquipped with an adjustable filling range between 2 ml and 1000 ml, the controller allows precise customization for various bottle and vial sizes. The programmable timing control feature makes it suitable for industries that require high versatility and accuracy in liquid dispensing. This ensures consistency and maintains product quality across every batch.

User-Friendly and Robust DesignFeaturing a digital touch keypad and a large LCD display, users can easily monitor and set parameters. The non-drip, stainless steel nozzles minimize waste and contamination. With overload and short circuit protection, this machine offers both operator safety and equipment longevity, all encased in durable ABS and mild steel housing.

Efficient and Versatile OperationThe Eight Head Liquid Filling Machine Controller is compatible with both glass and plastic containers, making it a versatile choice for various packaging applications. It supports automatic operation, quick batch counting, and can be mounted either on a tabletop or panel, giving flexibility in installation to suit workspace requirements.

FAQ's of Eight Head Liquid Filling Machine Controller:

Q: How does the Eight Head Liquid Filling Machine Controller ensure precise filling for different liquids?

A: The controller utilizes microprocessor-based timing and programmable control for each nozzle, allowing for fine-tuned fill volumes between 2 ml and 1000 ml. Its high-precision, non-drip stainless steel nozzles minimize spillage and maintain accurate dispensing across a range of liquid viscosities.

Q: What types of containers can this machine handle?

A: This filling machine controller is designed to work with both glass and plastic containers, making it suitable for automated bottling and vial filling in various industries.

Q: When should the programmable timing control be adjusted, and why?

A: Programmable timing control should be set according to the specific fill volume and viscosity of your product. Adjust it when changing to different bottle or vial sizes or when using new types of liquids, to ensure every container receives the correct amount.

Q: Where can the machine be installed for optimal use?

A: The controller offers flexible mounting options: it can be installed as a table top unit or panel mounted, allowing you to adapt it to your facility layout and workflow requirements.

Q: What is the typical process for using the machine?

A: Set your desired filling parameters using the touch keypad and LCD display, select the appropriate nozzle configuration, and load your containers. The machine will automatically dispense measured liquid volumes, count batches, and alert you to any errors, ensuring streamlined operation.

Q: How does this machine benefit my liquid packaging operations?

A: It increases operational efficiency and accuracy, reduces product waste with its non-drip nozzles, and automates batch counting. Its user-friendly interface and robust protection systems make it ideal for intensive industrial use, improving productivity and consistency in packaging.

Q: What accessories are included with the machine?

A: Each unit comes with a user manual, power cable, and mounting screws, ensuring you have everything needed for installation and operation right out of the box.