About Power Factor Controller Design

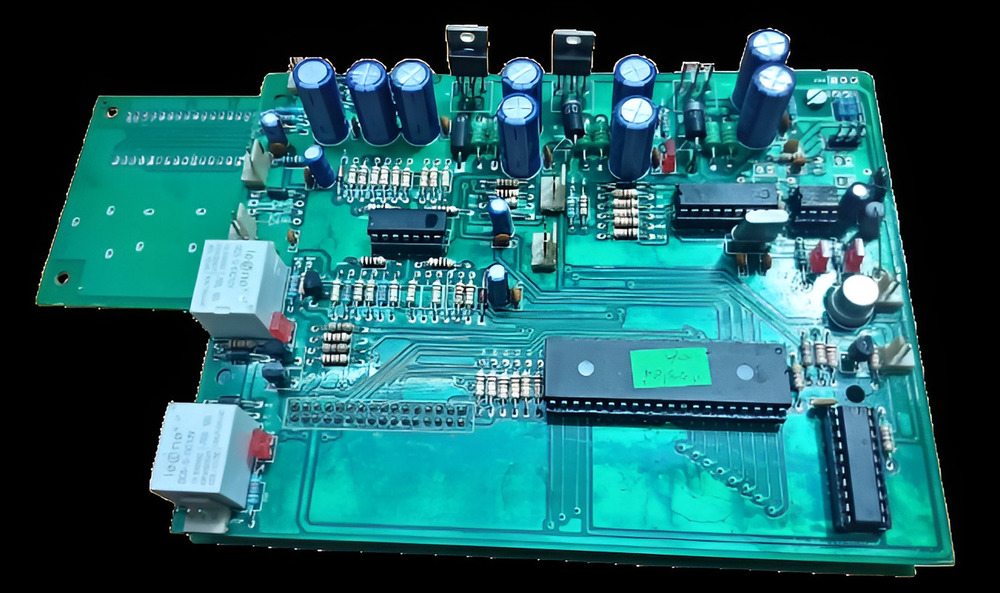

We are having more than 20 years of design experience and are specialize in all kind of Electronics and Embedded circuits designs in Microcontroller, Analog and Digital circuits, Power Systems, AHF Designs, SVG Designs, single Phase and Three Phase UPS and Inverters design, APFC Relays, SCR Switching Boards, IGBT Switching Boards, Motor Control Boards, battery-powered handheld devices, motor drivers and controllers, power systems, boards etc. Our expertise is in electronics circuit design services with a schematic design to final product. This includes selecting relevant electronic components based on the product requirements already present in the product requirements document. Additionally, we elaborate circuit design with actual electronic connections based on functional diagrams.

We do development from concept to final product.

Precision and Reliability for Industrial EnvironmentsEngineered to withstand challenging industrial conditions, our Power Factor Controller Design functions effectively between -10C and +50C, and tolerates humidity levels from 10% to 95% (non-condensing). The enclosure is constructed from ABS plastic with an IP54 rating, safeguarding internal electronics from dust and splashes, while its lightweight design ensures easy handling and installation. The unit's high measurement accuracy ensures optimal performance and energy savings.

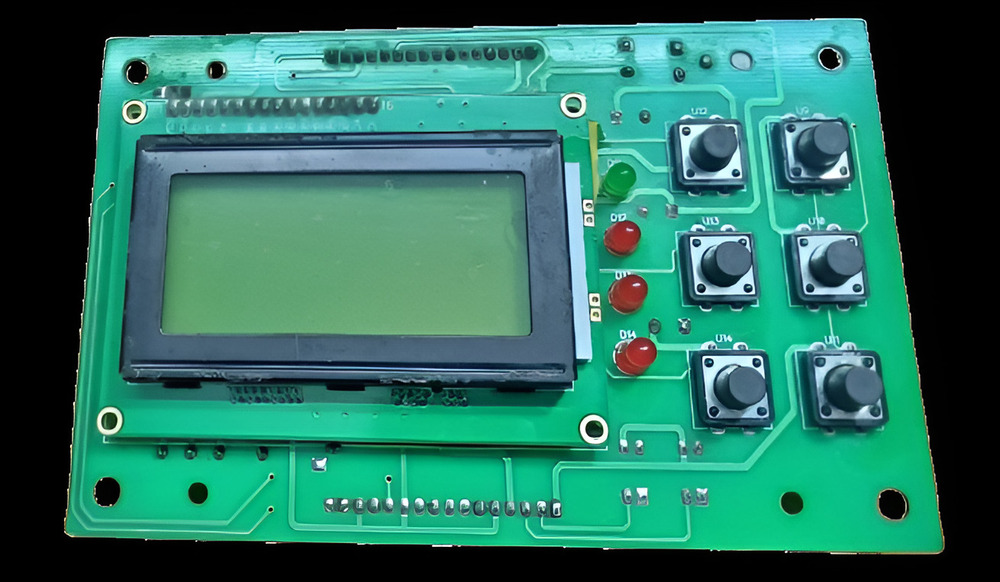

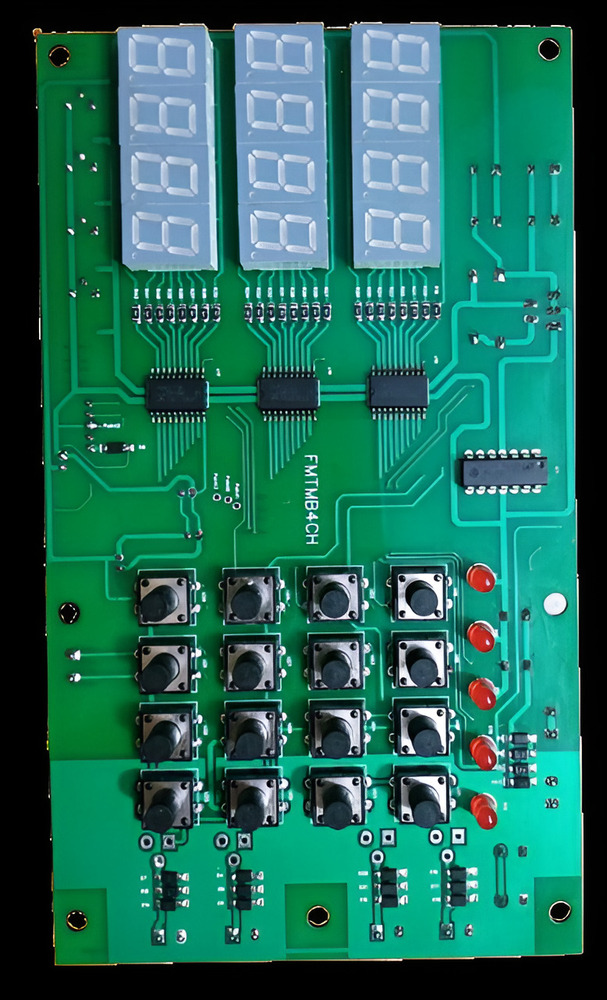

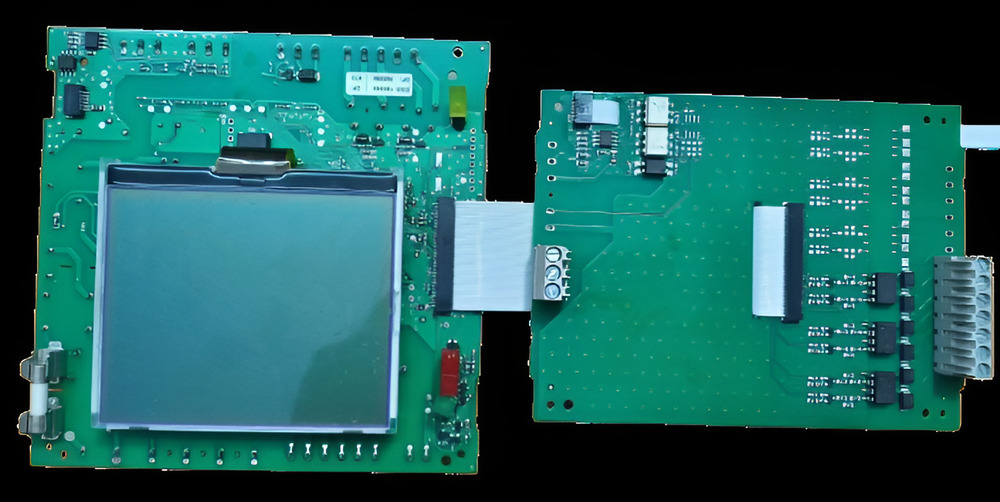

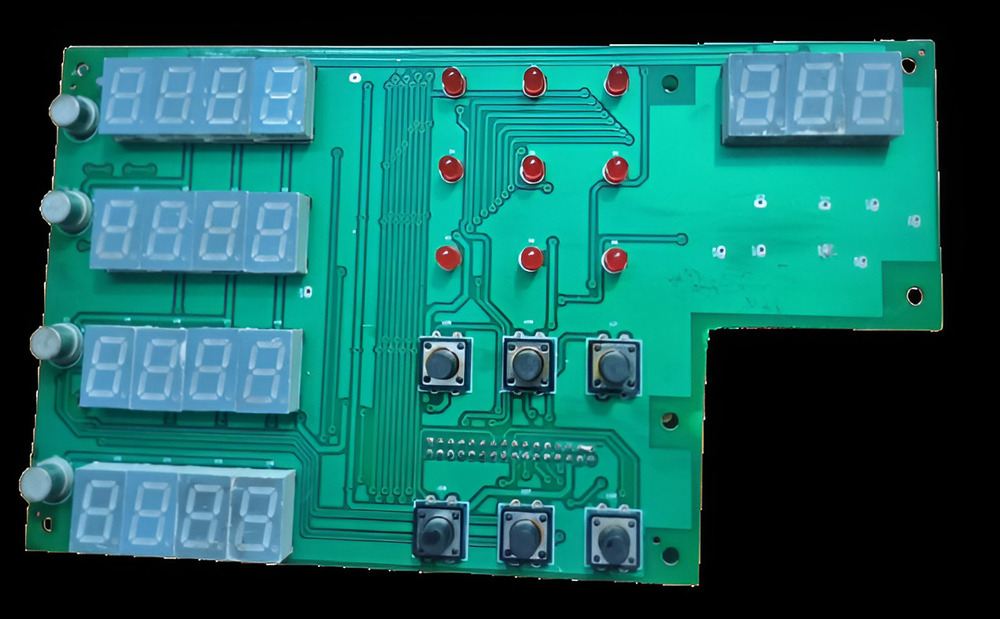

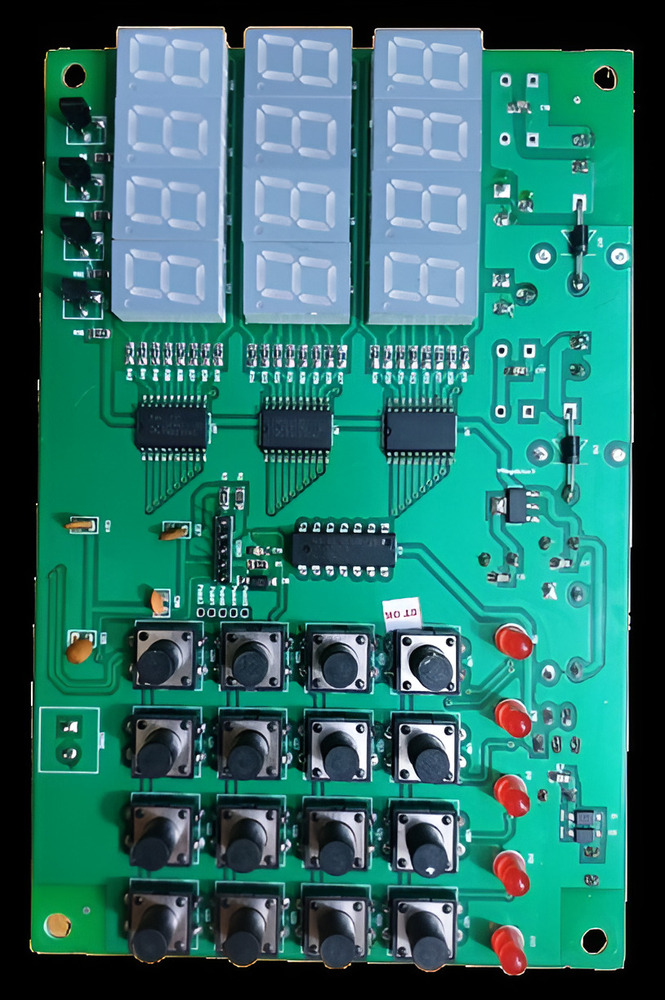

Advanced Communication and Control FeaturesFor seamless integration into modern control systems, the controller supports RS485 Modbus communication (optional), allowing real-time monitoring and management. Installation is straightforward thanks to its panel/surface mounting options, while automatic step switching and true RMS voltage sensing enable accurate and reliable power factor correction through up to 12 control relay outputs. The LCD digital display provides immediate feedback and simplified configuration.

FAQ's of Power Factor Controller Design:

Q: How does the Power Factor Controller Design improve energy efficiency in industrial applications?

A: By continuously monitoring and automatically adjusting reactive power compensation through up to 12 relay outputs, the controller maintains an optimal power factor. This reduces energy wastage, minimizes electricity bills, and helps avoid utility penalties for poor power factor.

Q: What are the installation requirements for this power factor controller?

A: The controller can be mounted on a surface or panel. It requires a three-phase power supply with an operating voltage range of 230-440V AC. Its compact size (150 mm x 120 mm x 60 mm) and moderate weight (approx. 600g) make it suitable for various industrial electrical panels.

Q: When should the RS485 Modbus communication port be utilized?

A: RS485 Modbus should be employed when remote monitoring, control, or integration with SCADA or building automation systems is desired. This optional feature enhances connectivity and facilitates real-time data exchange between the controller and supervisory platforms.

Q: Where is this power factor controller most effectively used?

A: It is most effective in industrial environments across India where three-phase power and reactive load fluctuations are prevalent. Common settings include manufacturing facilities, process industries, and commercial buildings with large inductive equipment.

Q: What is the process for power factor correction using this controller?

A: The controller analyzes real-time voltage and current parameters with true RMS sensing, then automatically switches capacitor steps via relay outputs to maintain the target power factor. Protection features ensure safe and reliable operation during voltage or load anomalies.

Q: How does the controller's LCD digital display enhance usability?

A: The LCD digital display provides clear, at-a-glance information about key parameters, diagnostics, and operational status. This simplifies configuration, monitoring, and troubleshooting for facility personnel, ensuring efficient management of the power factor correction system.

Q: What benefits does the enclosure's IP54 ABS plastic rating provide?

A: The IP54 rating combined with a robust ABS plastic enclosure ensures protection against dust ingress and water splashes, enhancing product durability and minimizing maintenance requirements in industrial settings.