About 4 Head Liquid Filling Machine Controller

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

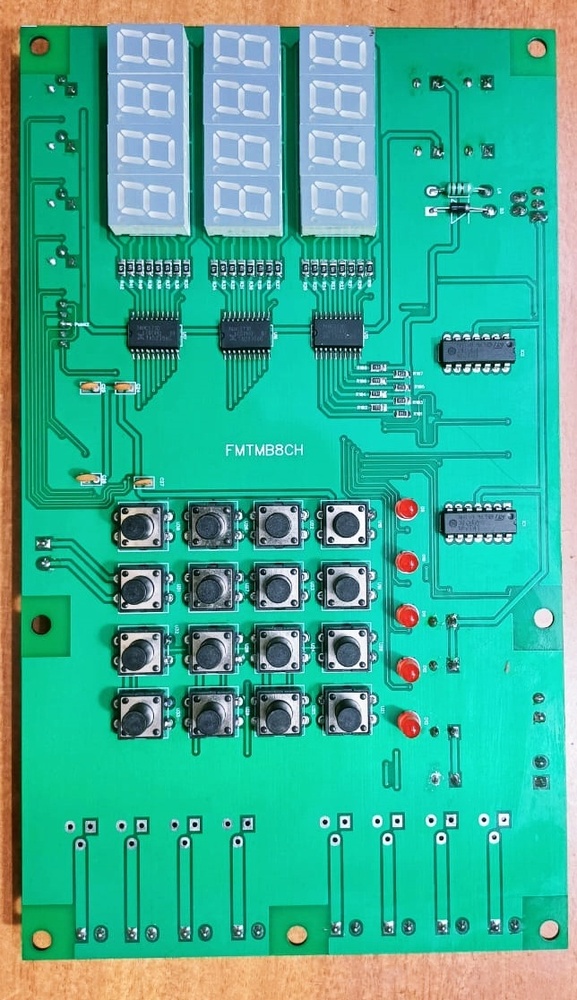

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Precision and Efficiency for Liquid FillingEngineered to support up to four filling heads, this controller guarantees uniform filling accuracy of 1%, making it suitable for industries where precision is essential. Digital programming and adjustment for each individual head help maintain consistent results, reduce wastage, and boost productivity.

Versatile Operation and User-Friendly DesignDesigned for ease of use, the controller features a clear 7-segment digital display and intuitive controls. Operators can select between manual and automatic modes, adjusting fill times for each head as required. The system supports both tabletop and panel mounting, ensuring convenient integration into varied setups.

Comprehensive Safety and DurabilitySafety is paramount, with overload and short circuit protection integrated into the design. The sturdy ABS enclosure and quality PCB electronics ensure long-term durability, even in challenging industrial environments with humidity levels up to 85% RH and temperature up to 45C.

Ideal for Diverse ApplicationsFrom pharmaceuticals and chemicals to food and cosmetics, this automated controller adapts to multiple liquid types and packaging formats. Its compatibility with bottles, jars, and containers in various materials makes it a versatile choice for manufacturers seeking efficiency and accurate dosing.

FAQ's of 4 Head Liquid Filling Machine Controller:

Q: How does the controller achieve accurate liquid filling across different heads?

A: The controller utilizes microcontroller-based digital technology and independent input controls for each filling head. This allows users to preset and adjust timers for each head, ensuring consistent filling volumes and accuracy up to 1%, depending on the liquid and operational setup.

Q: What types of containers and industries is the controller suitable for?

A: This liquid filling machine controller is compatible with bottles, jars, and containers made from various materials. It is widely used in pharmaceutical, chemical, food, and cosmetic industries where precise and reliable filling automation is required.

Q: When should I use manual versus automatic mode?

A: Manual mode is ideal for precise control during testing, setup, or small batch processes. Automatic mode is suited for high-throughput operations, allowing continuous and consistent filling with minimal operator intervention. Both modes are selectable according to production needs.

Q: Where can the controller be installed for optimal operation?

A: The controller is designed for flexible installation, supporting both tabletop and panel mount setups. This adaptability ensures it can be easily integrated into new or existing liquid filling stations for streamlined workflow.

Q: What safety mechanisms are incorporated in the controller?

A: To protect equipment and operators, the controller features integrated overload and short circuit protection. These safety measures help prevent accidents and ensure the long-term reliability of the controller during operation.

Q: How do I adjust the filling volume for each head?

A: The controller is equipped with programmable timers for each filling head. Users can easily set or modify the fill time using the digital display panel, allowing for quick adjustments to accommodate various liquid types and container sizes.

Q: What are the main benefits of using this liquid filling machine controller?

A: Users benefit from enhanced filling accuracy, user-friendly operation, reliable safety features, and flexible installation options. These qualities collectively improve productivity, reduce product loss, and streamline packaging processes in a wide range of industrial applications.