About 8 Head Liquid Filling Machine Controller

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

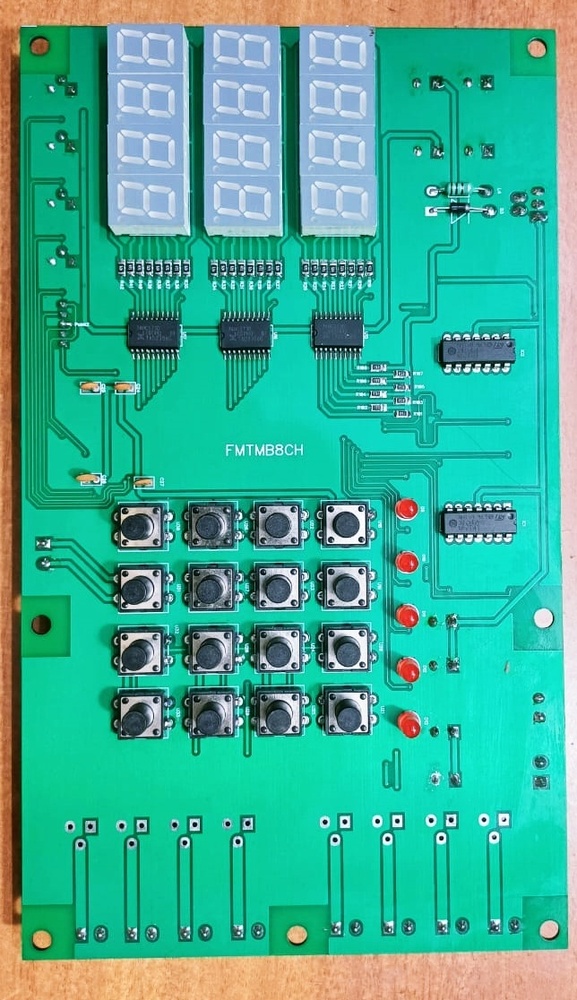

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Precision and Versatility in Liquid FillingEngineered for high accuracy and repeatability, this controller manages up to eight filling heads independently, facilitating seamless integration in diverse liquid bottling operations. Programmable fill volumes and flexible operation modes allow adjustment for various products, bottle sizes, and production needs.

Intuitive User Interface and Programmable OperationFeaturing a clear digital or LCD display, touch keypad, and programmable controls, setup and calibration are straightforward. Users can easily select or modify fill programs, adjust nozzle compatibility, and fine-tune each filling cycle, making the controller ideal for demanding production environments.

Built-in Safety and Reliable PerformanceWith integrated short-circuit and overload protection, this controller ensures safe, uninterrupted filling operations. Its robust construction using industrial-grade materials and microprocessor-based digital control system ensures dependable, consistent performance-crucial for high-throughput industries.

FAQ's of 8 Head Liquid Filling Machine Controller:

Q: How does the 8 Head Liquid Filling Machine Controller enhance filling efficiency?

A: With 8 independently controlled filling heads, programmable fill cycles, and fast switching between manual, semi-auto, and automatic modes, the controller can achieve up to 100 bottles per minute (depending on liquid viscosity and bottle size), maximizing productivity for varied liquid filling applications.

Q: What process is involved in setting up and operating this filling controller?

A: Setup involves mounting the controller on a tabletop or panel, connecting the filling nozzles, and selecting the operation mode. Use the touch keypad and digital display to program fill volumes, cycle times, and store multiple routines. The user-friendly interface ensures quick calibration and adjustment for various bottle types and liquids.

Q: Where can this controller be used, and what industries benefit from it?

A: This controller is ideal for use in pharmaceutical, food, chemical, and cosmetics industries, supporting both glass and plastic bottles. Its adaptable design makes it suitable for both small-scale labs and large-scale production facilities in India and beyond.

Q: What safety features are incorporated in the controller?

A: The controller includes built-in short-circuit and overload protection, safeguarding both the equipment and operators during use. These features are essential in maintaining safe and continuous operation in busy production environments.

Q: When should the programmable memory function be utilized?

A: The memory function is best used when multiple product types, bottle sizes, or recipes are being filled on the same line. Operators can store and quickly recall different fill programs, reducing setup time and ensuring consistent accuracy during production runs.

Q: How accurate is the dosing provided by this controller?

A: Thanks to microprocessor-based digital control, stepper motor drive, and straightforward calibration, the machine offers highly accurate and repeatable dosing for a filling range of 5ml to 1000ml per cycle. This reduces waste and ensures product uniformity.