About Process Control System

We are having more than 20 years of design experience and are specialize in all kind of Electronics and Embedded circuits designs in Microcontroller, Analog and Digital circuits, Power Systems, APFC Relays, SCR Switching Boards, IGBT Switching Boards, Motor Control Boards, SBC circuits, IoT sensor nodes, gateways, battery-powered handheld devices, wearables, BLE & WiFi devices, wireless products, sensors, AI & ML processors, motor drivers and controllers, power systems, boards etc. Our expertize is in electronics circuit design services with a schematic design to final product. This includes selecting relevant electronic components based on the product requirements already present in the product requirements document. Additionally, we elaborate circuit design with actual electronic connections based on functional diagrams.

We do development from concept to final product.

Experience working on Atmel, PIC, STM32, Nordic, and other Microcontrollers.

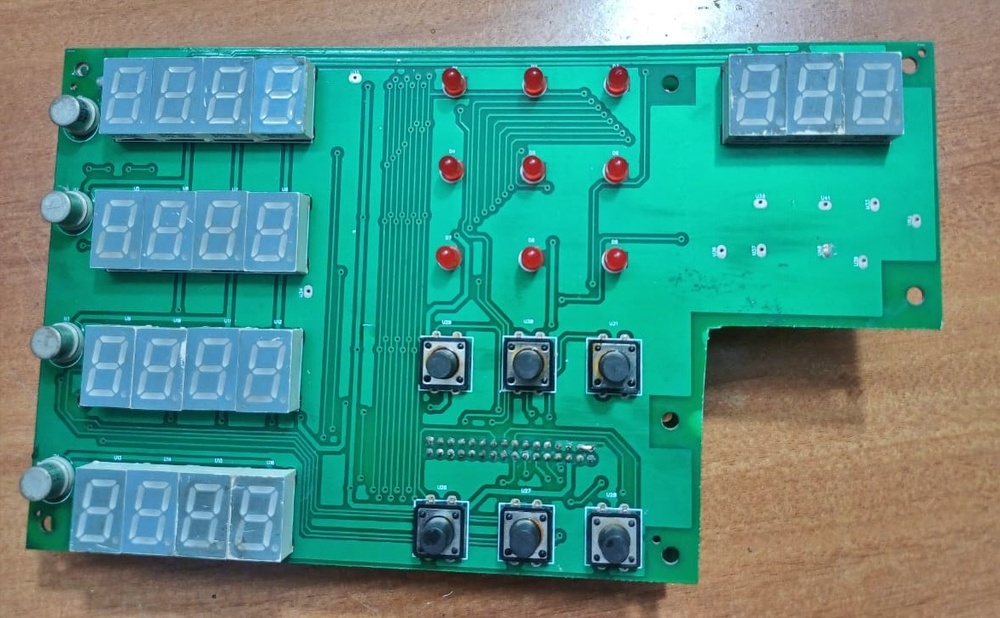

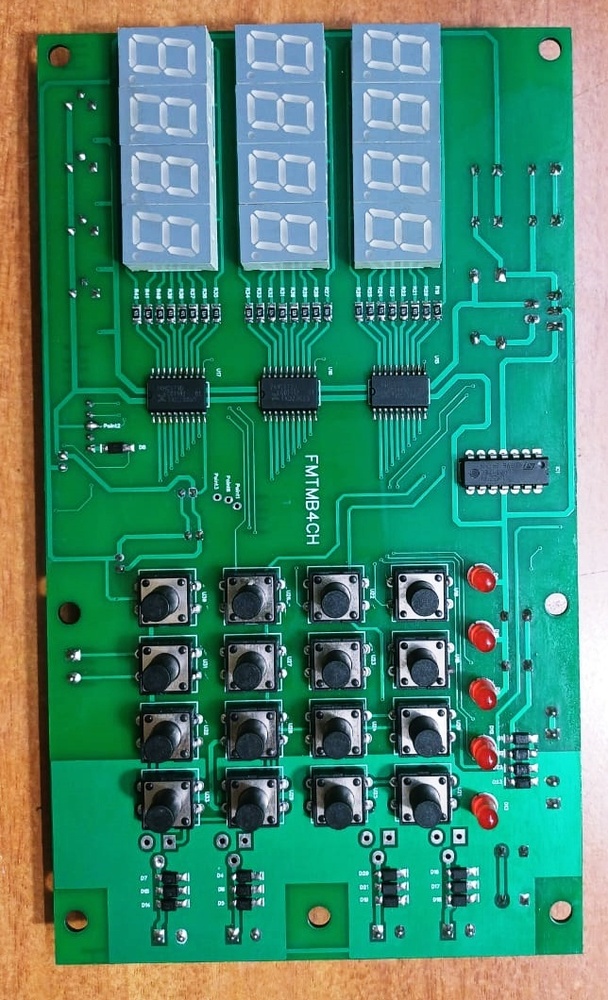

Versatile Communication and IntegrationEquipped with Modbus, Profibus, and Ethernet/IP protocols, the system easily communicates with a wide range of industrial networks, simplifying integration into existing process environments. With input flexibility for both analog and digital signals and output options for relay or transistor types, users enjoy comprehensive compatibility with diverse automation needs.

Reliable Performance in Demanding ConditionsDesigned for indoor industrial use, the system operates efficiently within 0C to 55C and offers protection levels of IP54 and IP65. This ensures reliable function amidst dust, water splashes, and varying environmental challenges. The rugged panel-mount design further enhances durability, making it a trustworthy choice for continuous plant operations.

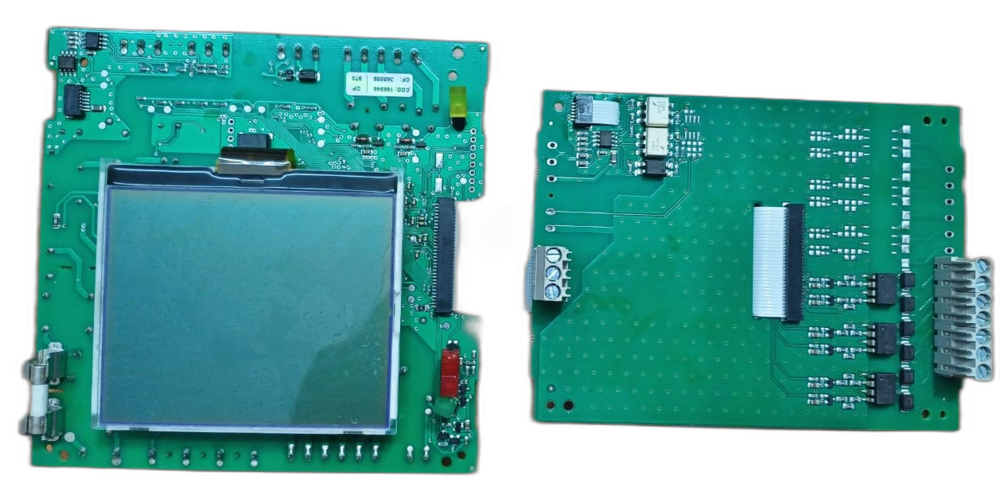

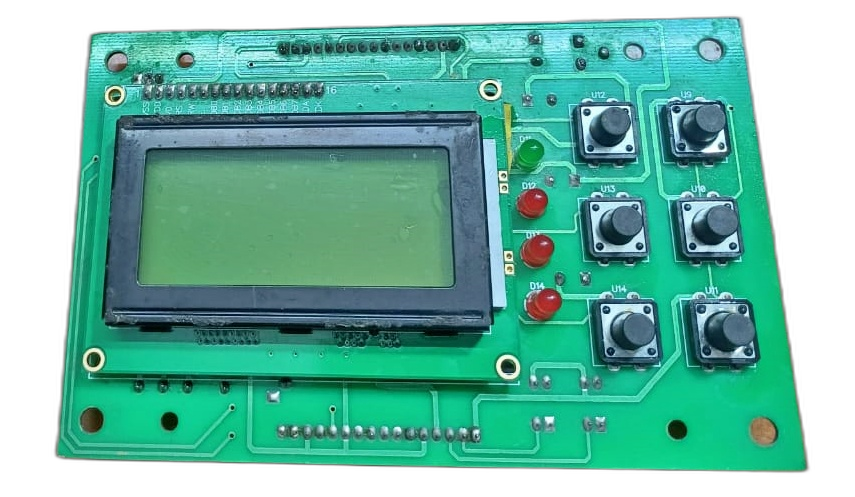

Advanced Monitoring and Expandable CapabilitiesExpandability is at the core of this process control system. Additional modules can be added as operational requirements grow, while the built-in data logging enables historical performance analysis. Combined with a clear digital/LCD display, users experience advanced diagnostics and streamlined monitoring, benefitting productivity and maintenance planning.

FAQ's of Process Control System:

Q: How does the panel-mounted Process Control System enhance industrial automation?

A: This system streamlines industrial automation by providing automatic control of processes through its flexible input/output options, strong communication protocols, and reliable panel-mounted design. It ensures continuous, precise operation and integrates seamlessly into plant control networks.

Q: What communication protocols are supported, and what benefits do they offer?

A: The system supports Modbus, Profibus, and Ethernet/IP, allowing for quick and reliable data exchange with other equipment. These protocols facilitate easy integration into widely used industrial networks, ensuring compatibility and enhanced operational efficiency.

Q: When should expandable modules be added to the system?

A: Expandable modules should be considered when operational demands increase, or when new functionality is needed such as additional input/output points or advanced data processing capabilities. This adaptability helps future-proof your automation investment.

Q: Where can the Process Control System be installed for optimal performance?

A: It is designed for indoor installations, ideally within environments that maintain temperatures between 0C and 55C. Its IP54/IP65 rating allows safe use in areas where exposure to dust or moisture is possible, common in many industrial settings in India.

Q: What is the process for using the data logging feature?

A: Once installed, users can activate data logging through the system's digital/LCD display interface. This allows ongoing recording of process data, which can later be accessed for analysis, helping with process optimization and maintenance scheduling.

Q: How does the system's protection class contribute to its reliability?

A: With IP54/IP65 protection ratings, the system is safeguarded against dust and water ingress. This enhances reliability and longevity, making it suitable for challenging industrial environments where such factors could otherwise threaten electronic equipment.