About 1 head Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

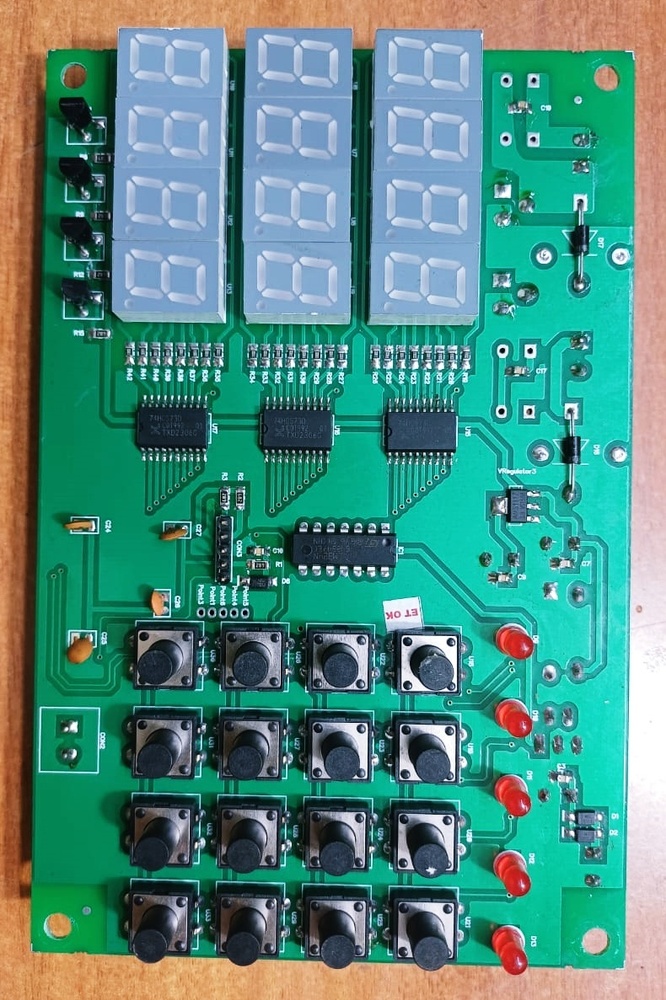

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Comprehensive Automation ControlThis PCB is optimized for seamless integration into liquid filling machines, catering to the demanding requirements of process automation. Its microcontroller compatibility allows for flexible system upgrades while ensuring precise operational control. The integrated proximity sensor enhances automation accuracy, promoting efficient and reliable liquid dispensing across industrial environments.

Quality Engineering and Robust ProtectionFabricated with FR4 epoxy glass and featuring a flame resistance level of UL94-V0, this PCB offers excellent mechanical strength and safety. It is safeguarded with a moisture-resistant coating and passes a 100% electrical test for reliability. The HASL-finished, burr-free surface, alongside white silkscreen legends, assures easy assembly and high-quality standards for Indian manufacturers, suppliers, and service providers.

FAQ's of 1 head Liquid Filling Machine PCB:

Q: How is this PCB mounted within a liquid filling machine?

A: The 1 head Liquid Filling Machine PCB is designed for panel mounting, allowing secure installation within machine enclosures using standard mounting hardware. This setup ensures stable mechanical placement and straightforward integration.

Q: What microcontrollers are compatible with this PCB?

A: This PCB supports popular 8051 and Arduino-type microcontrollers, providing flexibility for developers to program and control machine automation processes according to their specific requirements.

Q: When should the PCB be stored, and under what conditions?

A: The PCB should be stored in a cool and dry environment when not in use. Proper storage avoids exposure to heat and humidity, maintaining the moisture-resistant coating's effectiveness and extending the board's operational life.

Q: Where is this PCB typically used?

A: Primarily, the PCB is used in automation control for liquid filling machines. It's also suitable for other process control applications requiring reliable sensor integration and programmable logic.

Q: What is the process for connecting external devices or sensors to the PCB?

A: External devices or sensors can be connected using the provided screw terminals or pin headers, offering convenient and secure wiring. The integrated proximity sensor further simplifies sensor-based automation tasks.

Q: How does the moisture-resistant coating benefit users?

A: The moisture-resistant coating protects the PCB from environmental humidity, reducing corrosion risk and ensuring consistent performance in industrial or high-moisture conditions.

Q: What advantages does the smooth finish and RoHS compliance provide?

A: A smooth, burr-free surface finish ensures easy handling and assembly, while RoHS compliance guarantees the board is free from hazardous substances, supporting environmental health and safety standards.