About Double Head Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

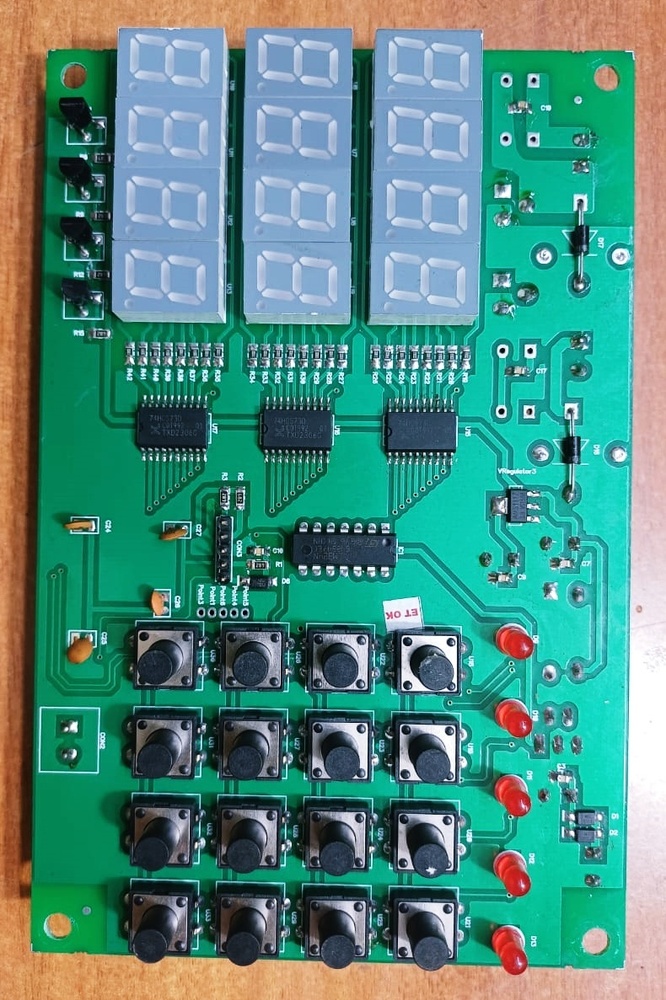

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Precision Engineering for Automatic Liquid FillingThis PCB is meticulously crafted to support double head liquid filling machines in automated environments. It integrates both through-hole and SMD components for enhanced flexibility and reliability, allowing seamless compatibility with level detection sensors. The PCB's design ensures accurate operation, enabling efficient and uninterrupted liquid filling process control.

Robust Construction and Superior Safety FeaturesConstructed on FR4 base material with a board thickness of 1.6 mm and 35 m copper, this PCB delivers durability along with UL94 V-0 flame resistance and RoHS compliance. Its stringent electrical testing (100% e-test) guarantees high insulation resistance and voltage endurance, making it suitable for demanding industrial applications.

Optimized for Easy Installation and MaintenanceThe screw terminal block connectors, ISP programming port, and labeled silkscreen make installation straightforward for technicians. A green LPI soldermask and white silkscreen ensure easy identification during assembly or maintenance, while antistatic bag packaging protects the board against electrostatic discharge during handling.

FAQ's of Double Head Liquid Filling Machine PCB:

Q: How is the Double Head Liquid Filling Machine PCB installed within the filling system?

A: The PCB uses screw terminal block connectors for secure and easy wiring, while its mounting holes and standard size facilitate fitting into most machine control panels. The presence of both through-hole and SMD components aids in straightforward integration.

Q: What benefits does the sensor switch compatibility provide for automatic liquid filling applications?

A: Sensor switch compatibility enables real-time liquid level detection, helping maintain precise fill volumes and preventing overflows. This feature enhances process accuracy and overall operational safety.

Q: When is it recommended to use this PCB in automated filling operations?

A: This PCB should be used whenever a consistent, reliable control solution is needed for double head liquid filling machines, especially where level detection and process automation are key requirements.

Q: Where is this PCB manufactured and can it be sourced locally in India?

A: The Double Head Liquid Filling Machine PCB is manufactured and supplied in India, making it accessible for local manufacturers, service providers, and suppliers.

Q: What is the recommended power supply and voltage tolerance for this PCB?

A: The board operates on a stable 12V DC input and can handle up to 250V AC voltage endurance, thanks to its high-quality construction and controlled impedance.

Q: How does using Altium Designer in PCB design improve quality and performance?

A: Altium Designer allows for precise layout, robust signal integrity, and advanced component placement, resulting in a reliable, high-performing PCB tailored for demanding industrial applications.