About Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

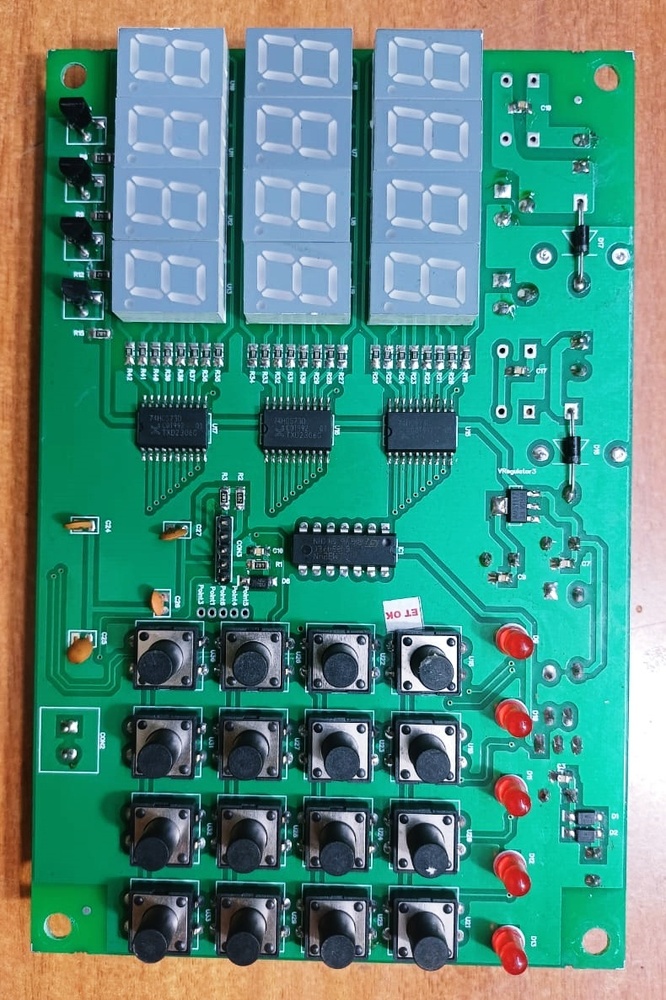

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Reliable Performance in Demanding EnvironmentsBuilt to operate comfortably between -20C and +60C, the board withstands challenging conditions while maintaining insulation resistance above 500 M and flame resistance rated UL94 V-0. Its 1.5 kV AC voltage endurance, controlled impedance, and robust HASL surface finish ensure durability and safety across demanding industrial applications.

Advanced Integration and Control FeaturesIntegrating a microcontroller for dedicated process control, the board supports both liquid level detection and automation, utilizing high-quality ICs, relays, connectors, and sensors. Custom firmware compatibility and straightforward screw terminal or header pin connectivity deliver flexibility for diverse system designs and upgrades.

Versatile Application with Industry StandardsCompliant with IPC-A-600 Class 2 and utilizing FR-4 epoxy glass with dual-layer design, the board is engineered for use in pharmaceutical, food, cosmetic, and chemical automation. Storage and operation are simplified by its resilient design, making it an optimal choice for continuous and precise liquid filling processes.

FAQ's of Liquid Filling Machine Board:

Q: How do I mount the Liquid Filling Machine Board in my equipment?

A: The board offers versatile mounting options, including panel mount and screw mount, making integration straightforward for various machine enclosures. Simply secure the board onto your control panel or mounting surface using the provided holes and appropriate screws for a stable installation.

Q: What types of liquids is this board compatible with, and in which industries can it be used?

A: This controller supports water, chemicals, beverages, and a range of industrial liquids, making it ideal for automatic filling machines in the pharmaceutical, food and beverage, cosmetic, and chemical industries.

Q: When is maintenance or testing required for optimal board performance?

A: The board undergoes a 100% functional test, including flying probe and E-testing before dispatch. For best results, periodic visual inspections and functionality tests during equipment servicing are recommended to ensure reliable performance and safety.

Q: Where should the board be stored when not in use?

A: It should be stored in dry, normal room temperature conditions to maintain its structural and electrical integrity. Avoid damp or extreme environments to prevent component degradation.

Q: What benefits does integrated process control offer for liquid filling applications?

A: The onboard microcontroller enables automated process control, liquid level detection, and compatibility with custom firmware. This enhances throughput, provides precise fill volumes, and reduces manual intervention, leading to increased efficiency and minimal wastage.

Q: How is the board connected to other equipment in the filling system?

A: Connections can be made via screw terminals and header pins, allowing flexible and secure integration with sensors, actuators, pumps, and the main control system. The clear silkscreen labeling on both sides aids in hassle-free wiring and setup.

Q: What process steps does the board handle in an automatic liquid filling machine?

A: The board manages critical steps such as level sensing, relay-based actuation, and microcontroller-driven logic for monitoring and controlling liquid fill cycles, resulting in accurate, repeatable fills and smooth operation within automated systems.