About 2 Head Liquid Filling Machine Circuit

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

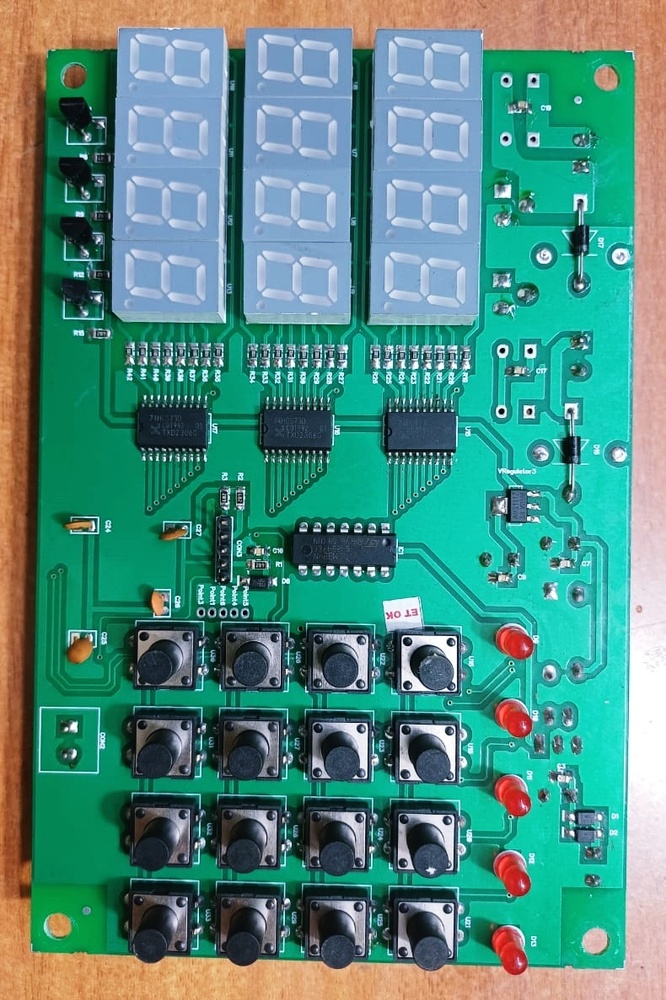

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Precision and Efficiency in Bottle FillingEngineered for consistency, the 2 Head Liquid Filling Machine Circuit provides an output of 10-30 bottles per minute, depending on the viscosity of the liquid. With independently controlled filling heads governed by a reliable microcontroller system, it assures high repeatability and minimal downtime, streamlining operations in commercial production environments.

Robust Construction and Safety ComplianceBuilt on a 2-layer, 1.6 mm thick FR4 epoxy glass board with controlled impedance design, this circuit withstands harsh industrial conditions. Key safety features include over 10^12 insulation resistance, a 1500V AC voltage endurance, and RoHS compliance. Its HASL surface ensures dependable solderability, while the flame-retardant design adds another layer of operational security.

FAQ's of 2 Head Liquid Filling Machine Circuit:

Q: How does the independent filling head control benefit production processes?

A: Independent, electrically controlled filling heads enable simultaneous or staggered operations, accommodating different bottle sizes or liquids. This feature optimizes throughput and minimizes cross-contamination or spillage, especially in multi-product filling lines.

Q: What steps are involved in installing the 2 Head Liquid Filling Machine Circuit?

A: Installation involves mounting the PCB securely within the filling equipment, wiring the 230V AC power supply, connecting the head actuators and compatible photoelectric sensors, then configuring the microcontroller settings as required. Always ensure installation is performed by qualified personnel to maintain safety and compliance.

Q: Where can the 2 Head Liquid Filling Machine Circuit be used?

A: This circuit is versatile for use in industrial filling machines across pharmaceuticals, beverages, chemicals, and cosmetics. Its robust design tolerates ambient temperatures from 0C to 45C, making it suitable for most factory environments in India.

Q: What are the main benefits of using this circuit in liquid filling machines?

A: Key benefits include precise microcontroller-based control for accurate fills, high output speed, energy efficiency (power consumption under 50W), and dependable relay/contact operation for device integration. Its durable PCB design ensures long-term reliability and low maintenance needs.

Q: How does the circuit ensure safety during operation?

A: Safety is maintained through RoHS-compliant materials, a high insulation resistance (>10^12 ), 94V-0 flame resistance, and voltage endurance up to 1500V AC. The board is also 100% electrically tested to guarantee operational safety before deployment.

Q: What types of sensor switches are compatible with this filling circuit?

A: The circuit is compatible with photoelectric sensor switches, which provide reliable detection and triggering of the filling process, ensuring consistent bottle presence and automated operation.