About Eight Head Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

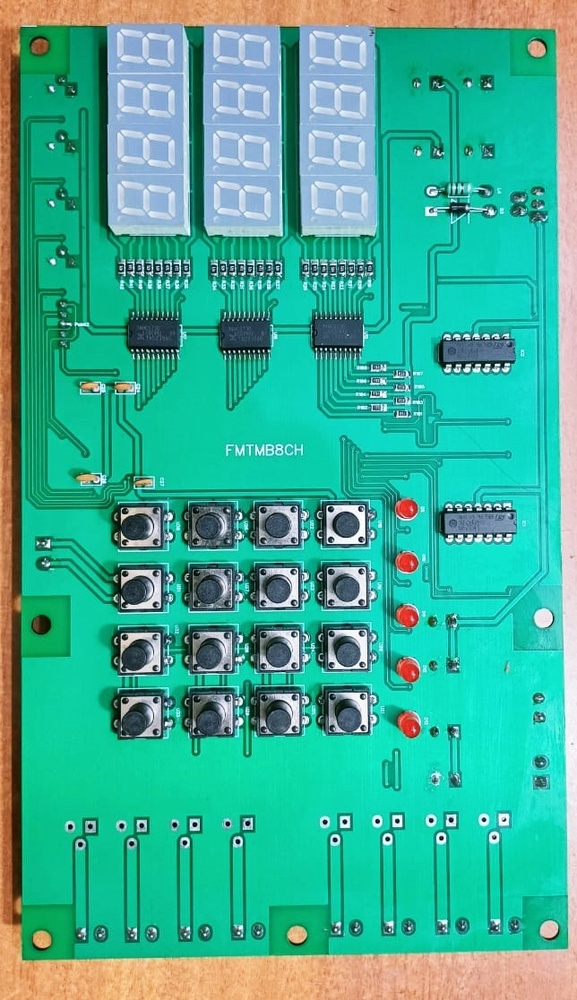

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Precision Engineering for Automated Liquid FillingThis PCB is tailored for eight-head automatic liquid filling machines, ensuring precise fluid control in industrial operations. Its mixed assembly (SMD and through-hole) and custom panel size facilitate easy integration into diverse machine configurations. With a temperature range of -20C to +70C and panel or chassis mounting, it adapts seamlessly to demanding production settings, optimizing machine performance and uptime.

Reliable Connections and Enhanced Safety FeaturesEquipped with heavy-duty screw terminal blocks and a 5A per channel capability, this PCB provides secure connections for input and output. Safety is amplified by integrated sensor switches for real-time level or position feedback and robust insulation resistance over 500M. UL94 V-0 flame resistance and lead-free soldermask ensure safe and compliant operation, even in harsh industrial environments.

Upgradeability and Testing AssuranceFirmware can be upgraded easily via the ICSP header, future-proofing your equipment. Each board undergoes 100% E-testing and thorough visual inspection to guarantee fault-free performance. The controlled impedance design, quality FR4 base, and HASL finish provide signal reliability and longevity, making it an excellent choice for machine manufacturers, service providers, and suppliers.

FAQ's of Eight Head Liquid Filling Machine PCB:

Q: How is the Eight Head Liquid Filling Machine PCB installed in a machine setup?

A: The PCB can be mounted directly onto a panel or chassis within your filling machine using standard mounting techniques. All input and output connections are made via screw terminal blocks, allowing for secure wiring and straightforward installation.

Q: What are the benefits of using a mixed through-hole and SMD assembly type for this PCB?

A: This mixed assembly approach combines the mechanical strength of through-hole components with the compactness and efficiency of SMD devices. It delivers high performance, easier serviceability, and better reliability in industrial automation environments.

Q: When should firmware be updated, and how is it done?

A: Firmware updates should be performed when new features, enhancements, or bug fixes are released. Upgrading is accomplished easily via the onboard ICSP (In-Circuit Serial Programming) header, ensuring your system stays current and secure.

Q: Where can the standard Eight Head Liquid Filling Machine PCB be used?

A: It is designed primarily for automatic liquid filling machines using eight dispensing heads and can be used by manufacturers or integrators of such equipment, especially for industries in India seeking robust, reliable, and safe PCB solutions.

Q: What safety and quality tests are performed on this PCB?

A: The PCB undergoes 100% electrical E-testing and comprehensive visual inspection to ensure zero defects. It also meets UL94 V-0 flame resistance and offers insulation resistance greater than 500M, confirming its suitability for demanding environments.

Q: How do integrated sensor switches enhance the usage of this PCB?

A: The built-in sensor switches provide accurate real-time detection of liquid levels or head positions, enabling automated control and preventing spillage or operational errors in the filling process.

Q: What are the process steps after receiving the PCB for integration?

A: Upon receiving the PCB, verify the panel size and mounting provisions, connect all necessary wiring through the screw terminal blocks, ensure sensor integration, and proceed to firmware setup or upgrades as required. Final checks can be done by observing the LED indicators and confirming proper operation before initiating full-scale machine use.