About Eight Head Liquid Filling Machine Circuit

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

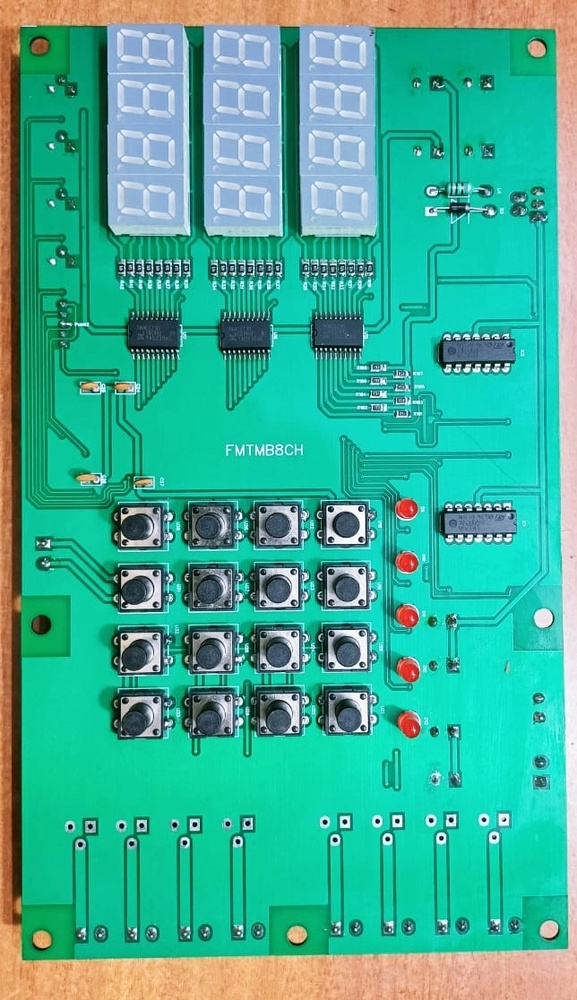

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Reliable and Adaptable Liquid Filling SolutionThis circuit is tailored for eight head automatic liquid filling machines and offers superb control over each nozzle. The microcontroller-based system guarantees precise cycle timing and easy adaptability for various liquid products. Featuring a 2-layer FR-4 PCB with a gloss finish and controlled impedance, the unit withstands demanding conditions, making it suitable for manufacturers and service providers seeking quality and customization in India.

Enhanced Safety and Robust Electrical DesignThe board employs high-grade materials, RoHS compliance, and a flame resistance of UL 94V-0 for maximum operational safety. With photoelectric and proximity sensors, electronic fuses, and connectors, the system supports safe mounting (through-hole or SMD) and is 100% electrically tested to IPC-A-600 Class 2 standards, ensuring reliability throughout its lifespan.

FAQ's of Eight Head Liquid Filling Machine Circuit:

Q: How is the cycle time of the Eight Head Liquid Filling Machine Circuit adjusted?

A: The cycle time can be easily adjusted between 0.5 to 10 seconds using the microcontroller-based control system. This feature allows users to customize the filling speed according to product or process requirements.

Q: What are the key benefits of individual electronic nozzle control?

A: Individual electronic nozzle control enables precise dosing for each liquid head, minimizing wastage, avoiding cross-contamination, and enabling flexibility in handling different liquids simultaneously within the same process.

Q: Where can the circuit be installed and in what environmental conditions does it operate best?

A: It is designed for installation within automated filling systems, typically in industrial environments. Optimal operation is at ambient temperatures of 0 to 50C and relative humidity of up to 85% RH.

Q: What process is followed for quality and safety testing of the PCB?

A: Each board undergoes 100% electrical testing according to IPC-A-600 Class 2 standards. The process checks insulation resistance (>10^8 Ohm), verifies all component placements, and ensures there are no shorts or open circuits.

Q: How can this circuit benefit manufacturers and suppliers in India?

A: Manufacturers and suppliers benefit from its customizable features, high operational reliability, RoHS compliance, and compatibility with modern eight head automatic filling machines, ensuring efficiency and high-quality results.

Q: When should maintenance or fuse replacement be performed?

A: Routine maintenance should be conducted as per the machine's overall schedule. The onboard 3A 250V fuse should be checked and replaced if there are signs of overload or circuit interruption, ensuring continual safe operation.