About Four Head Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

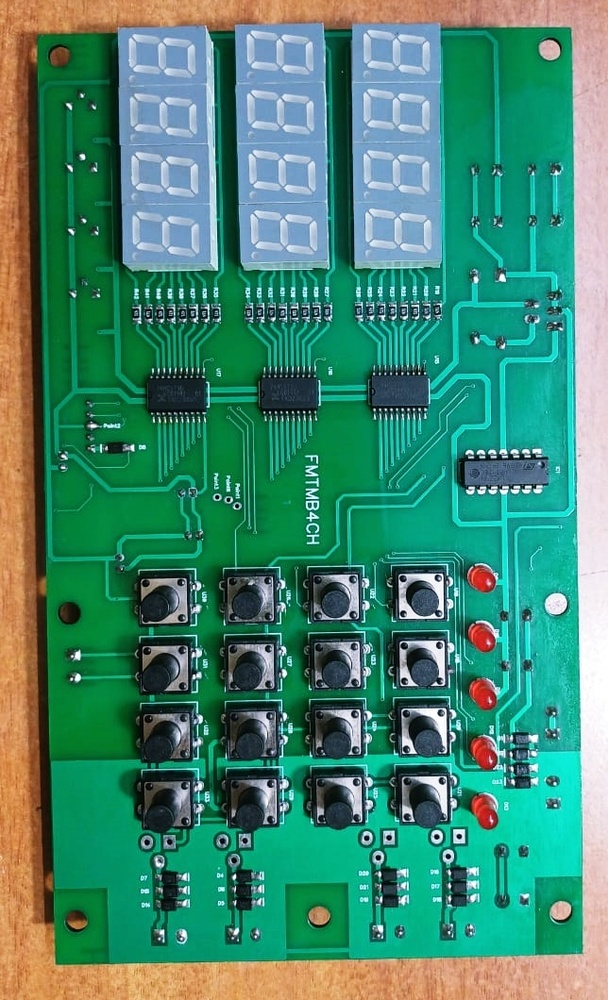

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Seamless Integration for AutomationSpecifically engineered for automatic four head liquid filling machine control, this PCB enables hassle-free integration into automation systems. Its compatibility with both photoelectric and proximity sensors, as well as mixed mounting (through-hole and SMD), ensures flexible connectivity and smart control, supporting a wide range of industrial applications with high accuracy and consistency.

Reliable and Durable DesignWith a robust FR4 base material, 1 Oz copper thickness, and conformal coating, the board withstands moisture, high voltage (AC 2500V/1min), and adverse environmental conditions. Quality is assured through complete E-testing, AOI, and batch-coded traceability, providing unmatched reliability for long-term operations.

FAQs of Four Head Liquid Filling Machine Board:

Q: How is the Four Head Liquid Filling Machine Board installed into an automation system?

A: The board features standard drilled mounting holes for easy attachment and is compatible with both screw and female header connectors, allowing straightforward installation into various control panels within automatic liquid filling machines.

Q: What is the recommended operating temperature range for this PCB?

A: The board is designed to operate efficiently within a temperature range of -20C to +70C, ensuring reliable performance in diverse industrial environments.

Q: When should traceability or batch codes be referenced for the board?

A: Batch-coded traceability is crucial during maintenance, warranty, or quality audits. Refer to the batch code for technical support or in the rare event of a recall.

Q: Where can this PCB be utilized effectively?

A: It is purpose-built for integration in automatic four head liquid filling machines, making it ideal for beverage, pharmaceutical, and chemical industries where precise fluid dispensing and automation are critical.

Q: What testing processes are applied to ensure PCB reliability?

A: Each board undergoes 100% E-test and Automated Optical Inspection (AOI), ensuring electrical integrity, correct assembly, and zero-defect performance before deployment.

Q: How does the PCB enhance the safety of liquid filling operations?

A: Protection features such as reverse polarity, short circuit, and overload protection prevent damage to both the PCB and connected equipment, safeguarding your automation process.

Q: What benefits does the board offer regarding environmental and regulatory compliance?

A: The PCB is RoHS-compliant and features a conformal coating, ensuring safety from harmful substances and moisture, and contributing to reliable, sustainable, and environmentally responsible operations.