About 2 Head Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

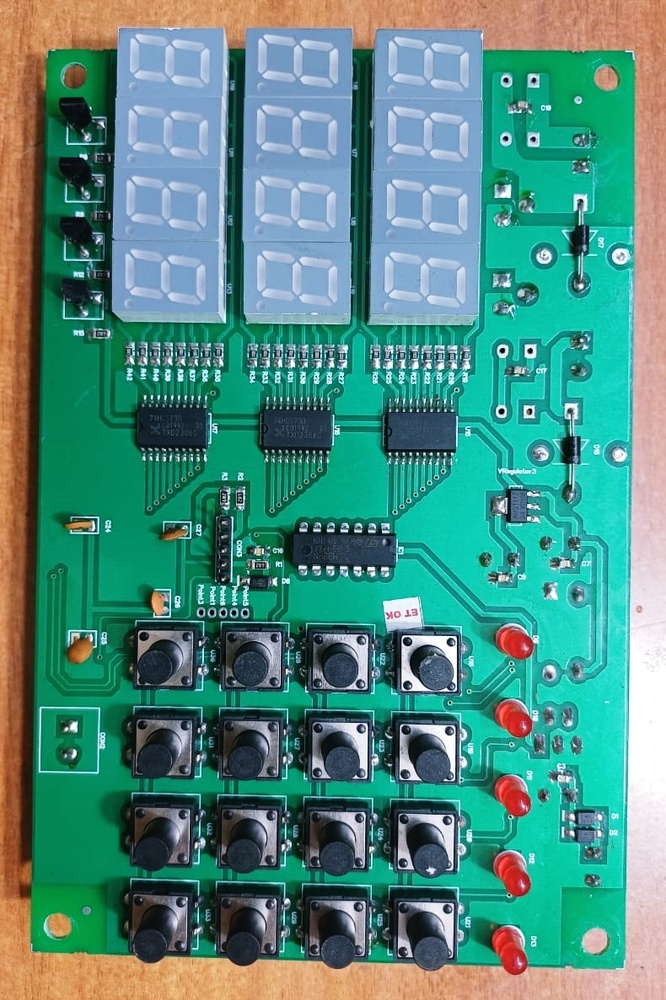

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Reliable Precision for Industrial AutomationDesigned specifically for liquid filling automation, this board delivers reliable and accurate results, essential for pharmaceutical, chemical, and food industries. The onboard microcontroller enables precise control, while fast sensor response maximizes throughput and minimizes error. Its robust construction and RoHS compliant materials ensure long-term, safe operation in demanding environments.

Optimized for Easy Installation and MaintenanceFeaturing a user-friendly panel mount design and screw terminal blocks, installation is straightforward and secure. The mixed assembly of SMD and through-hole components facilitates both performance and future servicing. Comprehensive ESD-safe packaging ensures product integrity during delivery and storage, making it an ideal choice for manufacturers, service providers, and suppliers alike.

FAQ's of 2 Head Liquid Filling Machine Board:

Q: How do I install the 2 Head Liquid Filling Machine Board in my system?

A: The board is designed for easy panel mounting and connects via screw terminal blocks. Follow the included installation guide, secure the board onto your control panel, and use the labeled terminals to connect input sensors, power, and output to actuators.

Q: What types of liquid filling applications is this board suitable for?

A: This board is ideal for automated liquid filling in pharmaceutical, chemical, and food industries, supporting a range of liquids that require precise and responsive control during bottle or container filling processes.

Q: When should the board be used in the production process?

A: Integrate the board at the automated filling stage, just before sealing and packaging. It ensures consistent, precise liquid volumes are dispensed, optimizing efficiency and maintaining quality standards.

Q: Where can I mount the board within my facility?

A: The compact design and robust panel mount make it suitable for control cabinets or dedicated operating panels in cleanrooms or production halls, as required by the application environment.

Q: What are the main benefits of using a microcontroller-based filling board?

A: A microcontroller-based system delivers more precise control, reduces error margins, and allows fast response to sensor input, leading to improved productivity and reduced product loss.

Q: How does the integrated photoelectric sensor switch enhance operation?

A: The integrated photoelectric sensors offer rapid response times (<50 ms) for detecting containers, ensuring reliable operation and helping to prevent spillage or overfilling during the filling process.