About 4 Head Liquid Filling Machine Circuit

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

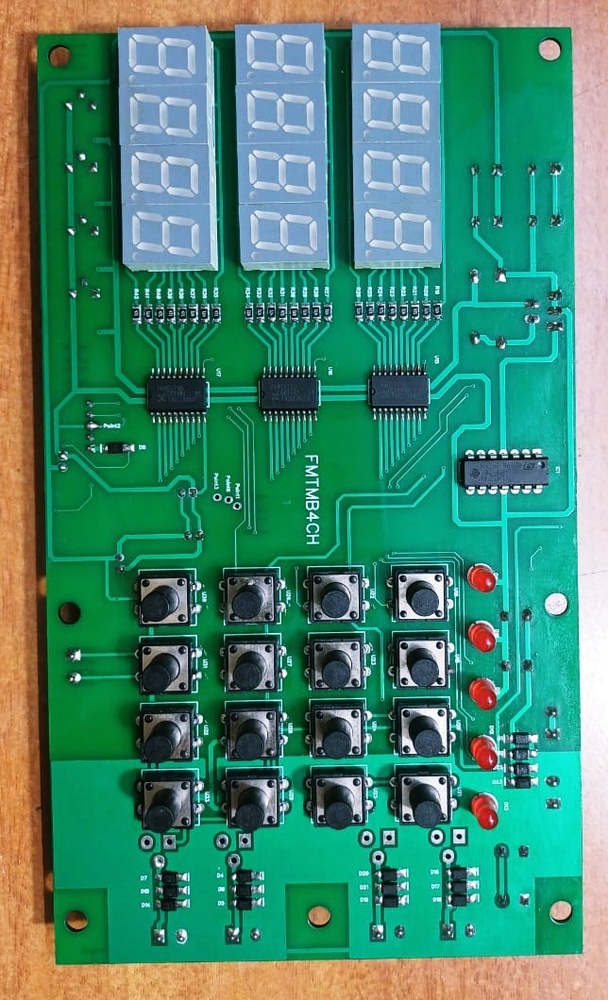

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Precision Engineering for Consistent ResultsThe 4 Head Liquid Filling Machine Circuit delivers a filling accuracy of 1%, ensuring consistent and reliable results for industrial liquid packaging. Its microcontroller-based control and solenoid valve drivers enable precise dispensing, while dedicated status indicators and LCD display enhance operational transparency and troubleshooting.

Durable, User-Friendly ConstructionManufactured with double-sided, FR-4 epoxy glass PCB and finished with HASL, this circuit is built for durability and stability. Its panel and chassis mount options provide installation flexibility, and screw terminal connections allow for straightforward electrical integration. A 5A glass fuse protects the unit, promoting operational safety.

Flexible Control and Smart InputsThe unit is equipped with start/stop switches and supports multiple sensor inputs, including photoelectric and capacitive types, to handle a wide range of liquid filling applications. Solenoid valve outputs enable automated control, significantly streamlining production processes.

Designed for Versatile Industrial EnvironmentsWith its robust construction and wide working temperature and humidity ranges, the circuit is suitable for various manufacturing environments across India. Its compact size and light weight make it easy to integrate into new or existing panel setups, supporting efficient production workflows.

FAQ's of 4 Head Liquid Filling Machine Circuit:

Q: How do I install the 4 Head Liquid Filling Machine Circuit?

A: Installation is straightforward, as the circuit is designed for both panel and chassis mounting. Secure the unit in your chosen location, connect the input and output terminals via the screw terminals, and ensure the power supply (220V AC or 24V DC) is correctly wired as per the instructions.

Q: What types of sensors are compatible with this filling machine circuit?

A: The circuit accepts both photoelectric and capacitive sensors as input, allowing flexible adaptation for different types of liquids and container detection in various automation setups.

Q: When should the 5A glass fuse be replaced?

A: The 5A glass fuse provides protection against electrical surges or faults. Replace it only when it is visibly blown or if the circuit stops functioning due to an overcurrent event. Always use an equivalent rated fuse to maintain safety and device integrity.

Q: Where is the status of the filling process displayed?

A: All operational status and key information are shown on the integrated 16x2 character LCD display. This screen provides real-time updates, error messages, and system status during operation.

Q: What is the process for starting and stopping the filling operation?

A: Starting and stopping the filling process is controlled via the start/stop switch input. Simply toggle the designated switch to begin or halt the filling cycle as required by your production process.

Q: How does the circuit benefit industrial liquid filling applications?

A: This circuit delivers high filling accuracy (1%), improves process consistency, and supports automation with controlled solenoid valve outputs. Its robust, safe, and flexible design enhances productivity and ensures reliable operation in demanding industrial settings.