About Volumetric Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

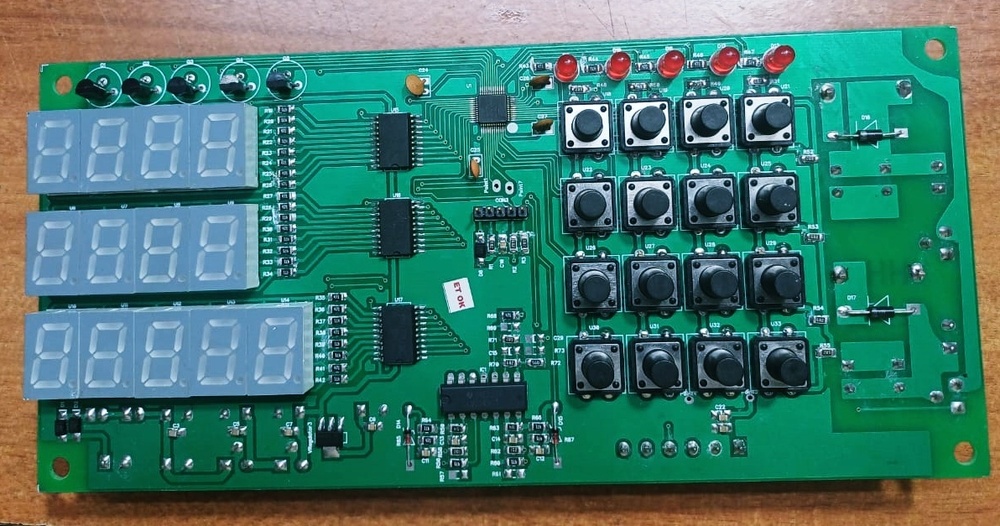

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Robust Design and Reliable PerformanceThis PCB utilizes both surface-mount and hand soldered components for versatility and resilience. The single-layer FR4 construction and HASL surface finish assure stability under varied operational temperatures. With a frequency response up to 50 Hz and a weight of approximately 50 grams, the VLFM-2024 is specifically engineered for liquid filling automation and general industrial process control.

Simple Integration and Versatile MountingEquipped to handle both through-hole and SMT mounting, this board seamlessly integrates into existing systems using standard screw terminals or JST connectors. Compatibility with optical or proximity sensor switches enhances its adaptability in automated environments, and anti-static bag packing ensures component integrity during transit and storage.

FAQ's of Volumetric Liquid Filling Machine PCB:

Q: How do I mount the Volumetric Liquid Filling Machine PCB in my system?

A: The PCB supports both through-hole and SMD mounting, making it suitable for various installation methods. It comes with screw terminals and JST connectors for secure and reliable electrical connections within automated systems.

Q: What is the recommended operating environment for this PCB?

A: This PCB performs optimally in temperatures ranging from -20C to +70C, with a standard humidity tolerance for industrial environments, thanks to its FR4 construction and green soldermask.

Q: When can I request a replacement for a faulty PCB?

A: A replacement can be requested within the warranty period only if the defect is due to manufacturing issues. The board must be returned in compliance with the supplier's replacement policy.

Q: Where can this PCB be used?

A: This PCB is ideal for liquid filling machines and general industrial applications requiring process control automation. Its robust design is suitable for use in factories and automated production facilities.

Q: What are the key benefits of using this PCB?

A: Users benefit from its wide temperature tolerance, compatibility with various mounting and connector types, reliable electrical test certification, and controlled impedance for stable operation in automated environments.

Q: How does the manufacturing process ensure quality and performance?

A: Manufacturing combines SMT and hand soldering, followed by a 100% electrical test. This ensures high-quality assembly, stable connectivity, and minimal defects, meeting strict industrial-grade standards.

Q: What sensors are supported by the PCB for automated control?

A: The board is compatible with optical and proximity sensor switches, making it convenient for integration into automated liquid filling and process control systems.