About Double Head Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

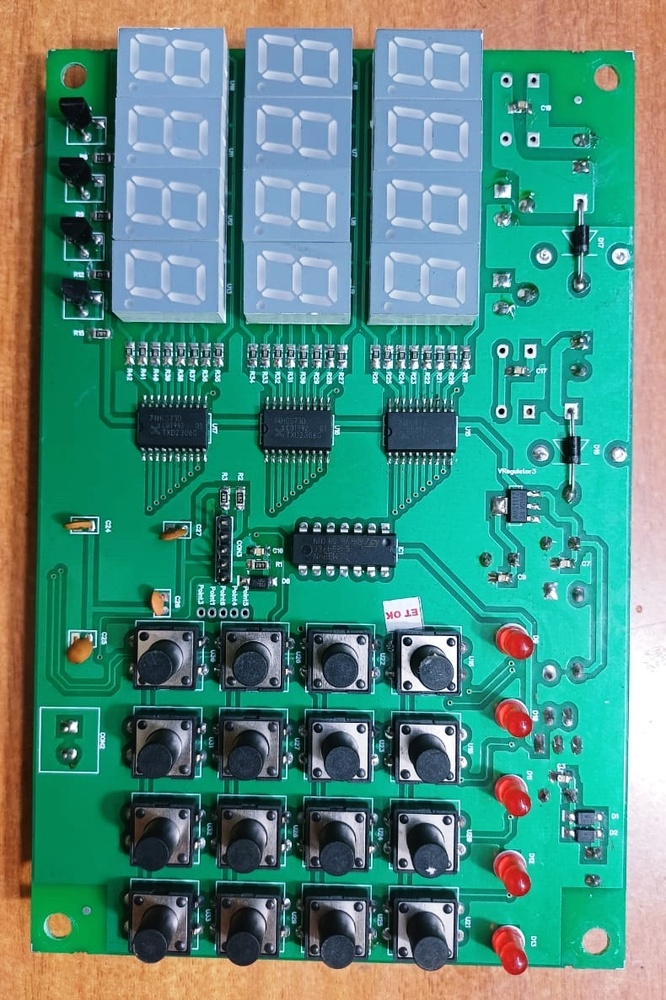

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Enhanced Automation for Liquid Filling OperationsOptimize your double head liquid filling processes with this advanced machine board. Engineered for automation, it integrates seamlessly with standard filling machines and provides stable, responsive control under demanding industrial conditions. Its combination of SMD and through-hole technology ensures durability and ease of maintenance, while the included sensor switch enhances operational efficiency.

Reliable Performance in Diverse EnvironmentsWith an operating temperature range of -20C to +70C and an impressive voltage endurance of 2,500 V AC per minute, this PCB is built for versatility and safety. Its green soldermask, 1.6 mm thickness, and strict adherence to IPC-A-600 Class 2 guarantee dependable performance and compliance, even in challenging manufacturing environments.

FAQ's of Double Head Liquid Filling Machine Board:

Q: How is the Double Head Liquid Filling Machine Board installed?

A: The board can be installed using either screw terminal or pin header connectors, catering to both automated and manual assembly processes. Clear silkscreen markings on the top side assist with precise placement and orientation during installation.

Q: What are the main benefits of using this PCB in liquid filling machines?

A: This board provides stable automation control, high operational reliability over a wide temperature range, and compliance with rigorous IPC-A-600 Class 2 and RoHS standards. The pre-mounted components and included sensor switch simplify setup and maintenance, enhancing productivity and safety.

Q: When should I consider replacing or upgrading the PCB?

A: It is recommended to replace or upgrade the PCB if you experience erratic machine control, visible component damage, or if new features or standards are required for your production line. Regular inspection as part of routine maintenance extends operational lifespan.

Q: Where can this board be used?

A: This PCB is designed specifically for double head liquid filling machines and is suitable for use in factories, laboratories, and production facilities that require precise liquid dispensing in varied environmental conditions.

Q: What is the process for quality assurance with this product?

A: Each board undergoes 100% electrical testing to verify circuitry integrity, compliance with IPC-A-600 Class 2, and functionality of pre-mounted SMD/THT components, ensuring consistent quality and dependability before delivery.

Q: How does the built-in sensor switch enhance the machine's usage?

A: The mounted sensor switch enables real-time operation feedback and can automate start/stop functions for liquid dispensing, increasing reliability and minimizing manual intervention during filling processes.