Talk to us

08045476295

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

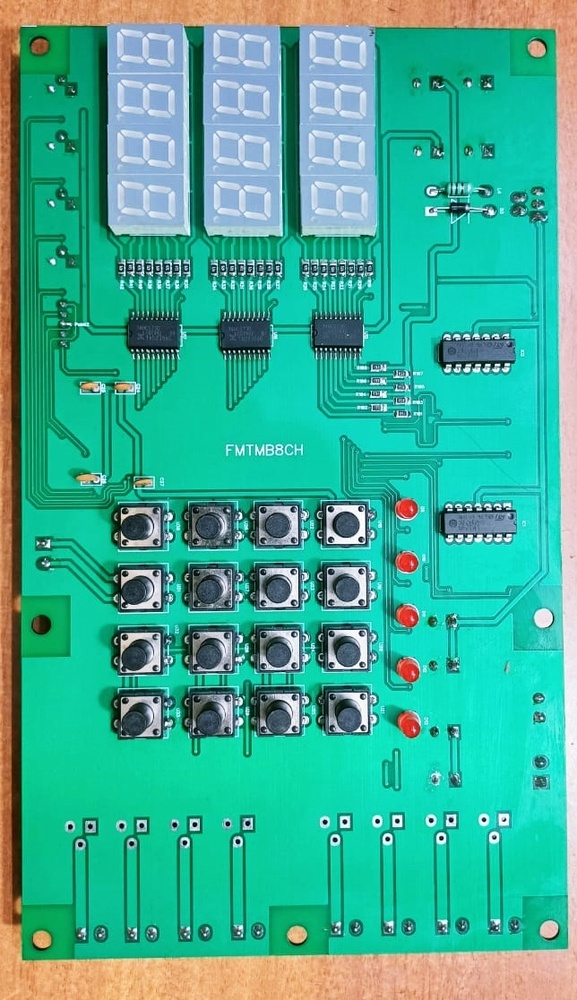

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Price:

Price 6000 INR / Number

Minimum Order Quantity : 1 Number

Electrical Components : PLC, Relay, Capacitor, Timer Circuit

Test : Other, 100% Functional Testing

Surface Finish : Other, HASL (Hot Air Solder Leveling)

Number Of Layers : Other, 2

Price 3500 INR / Number

Minimum Order Quantity : 1 Number

Electrical Components : Microcontroller, solenoid driver, relay, LED indicators, capacitors, resistors, diodes

Test : Other, 100% Etest, Visual inspection

Surface Finish : Other, HASL (Hot Air Solder Leveling)

Number Of Layers : Other, 2

Price 6000.00 INR / Number

Minimum Order Quantity : 1 Number

Electrical Components : Diodes, Relay, Microcontrollers, Transistors, Capacitors, Connectors

Test : Other, 100% Electrically Tested

Surface Finish : Other, HASL (Hot Air Solder Leveling)

Number Of Layers : 2 Layer

Price 6000 INR / Number

Minimum Order Quantity : 1 Number

Electrical Components : Microcontroller, relays, connectors, Tactile switches, optocouplers, capacitors, resistors, LED indicators

Test : Other, 100% Etesting and visual inspection

Surface Finish : Other, HASL (Hot Air Solder Leveling)

Number Of Layers : Other, 2 Layers