About Liquid Filling Machine Circuit

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

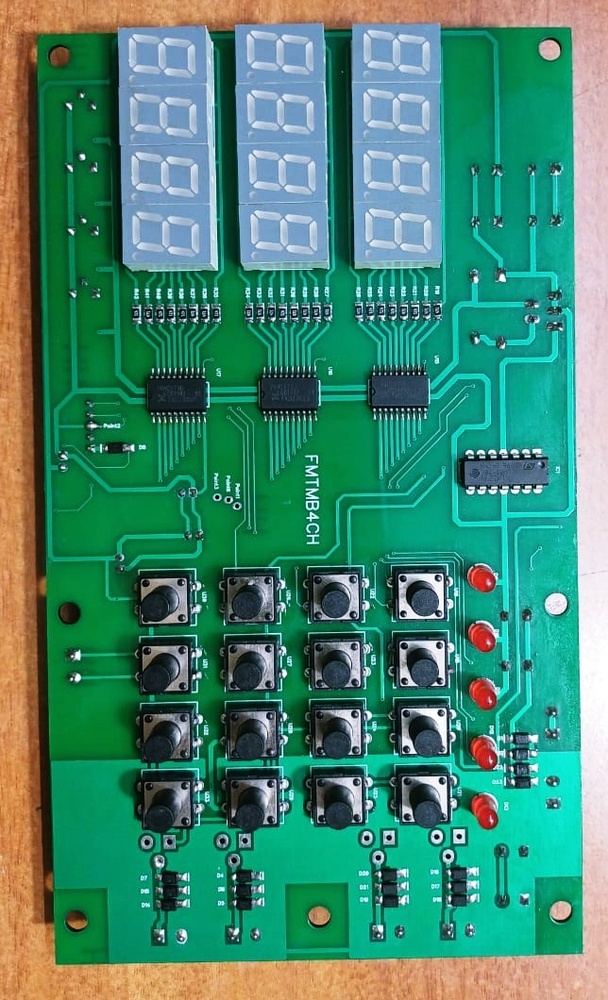

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Versatile Design & Easy IntegrationBuilt for automatic liquid filling and bottle packaging machinery, this circuit board supports both AC and DC power supplies, providing flexibility in deployment. Its compact panel size and ready-made mounting holes make installation straightforward, while the green, rigid PCB construction boosts durability. Suitable for new installations or retrofit upgrades, it easily interfaces with other components via convenient screw terminal blocks.

Advanced Protection and ComplianceThe circuit features robust safety mechanisms including reverse polarity and overcurrent protection to minimize risks during operation. RoHS compliance and UL94-V0 flame resistance offer additional assurance for industrial use. A thorough 100% E-test and visual inspection ensure each PCB meets stringent quality standards, making it a trustworthy solution for businesses demanding consistent performance.

Programmability for Customized AutomationFeaturing dedicating microcontroller-based logic support, this liquid filling machine PCB allows for customized routines and integration with infrared liquid level sensors. The programmable nature opens possibilities for tailored automation sequences matching specific production needs, streamlining workflow and increasing throughput in diverse environments.

FAQ's of Liquid Filling Machine Circuit:

Q: How can the Liquid Filling Machine Circuit be installed in my packaging machinery?

A: The board is designed with pre-drilled panel mounting holes for straightforward installation into standard control panels. Simply secure using appropriate hardware and connect I/O, power, and sensors via the screw terminal blocks. Follow your equipment manufacturer's guidelines to ensure safe and effective integration.

Q: What are the main advantages of using this programmable liquid filling circuit?

A: This circuit provides reliable, automated liquid filling with precise control, thanks to microcontroller-based programming and infrared sensor support. It also enhances safety with built-in protection features and is suitable for high-throughput bottle packaging lines, delivering flexibility, efficiency, and durability.

Q: When is it suitable to use the optional 12V DC input instead of mains AC input?

A: Use the 12V DC input in environments where AC mains power is unsuitable or unavailable, or when specific safety or equipment requirements necessitate low-voltage operation. The circuit's dual input design ensures compatibility in a wide range of installation scenarios.

Q: Where can this PCB be deployed within a liquid filling system?

A: This board is ideally panel-mounted inside the control or automation cabinet of your liquid filling or packaging machinery. It's engineered for industrial environments, with an operating temperature range from -10C to +60C, making it versatile for most factory settings.

Q: What is the process for programming the logic functions on this board?

A: The board includes microcontroller support, allowing users to develop custom automation sequences using standard programming tools compatible with the onboard microcontroller. Consult the user manual for programming steps and interface details.

Q: How does this circuit support precise liquid filling operations?

A: It interfaces with infrared liquid level sensors for accurate detection and uses programmable logic to ensure exact dosing. Solenoid drivers and relays control pump or valve operations, allowing for responsive, reliable filling in automated production lines.

Q: What maintenance or inspection steps are recommended for this PCB?

A: Routine visual inspection for dust, corrosion, or loose terminal connections is advisable. Ensure protection features remain functional and keep operating conditions within the specified temperature and voltage limits to maximize longevity and performance.