About 4 Head Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

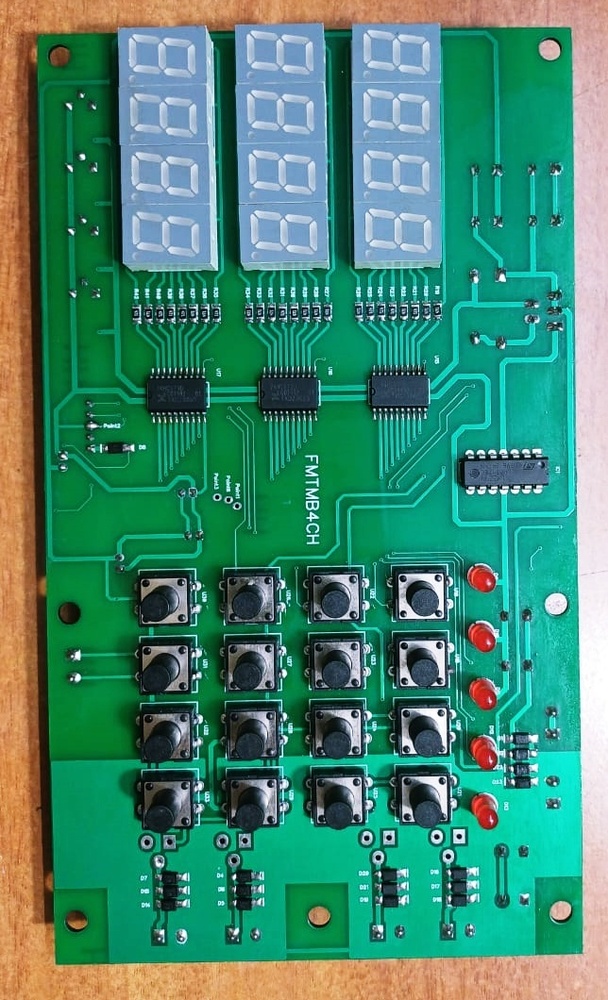

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Advanced Automation for Industrial EnvironmentsBenefit from high-grade engineering with this 4 Head Liquid Filling Machine Board. Designed for industrial automation, it manages multiple liquid filling heads with reliability in harsh conditions. With its robust microcontroller, relay integration, and compatibility with photoelectric sensors, you get an optimized solution for consistent fluid measurement and dispensing.

Versatile Mounting and Connectivity OptionsInstall this board effortlessly on panel or DIN rail setups to suit your operations layout. It features pluggable screw terminals and pin headers, allowing quick, secure connections for sensors, actuators, and controller interfaces. This flexibility means smooth integration into both new and existing systems.

Reliable Performance and ComplianceTested to withstand extreme temperatures and electrical demands, the board features RoHS compliance, 100% E-testing, lead-free HASL finish, and strict insulation standards. These ensure safe and reliable operation for diverse liquid handling needs, maintaining performance in demanding industrial settings.

Easy Upgrades and CommunicationEnjoy straightforward system updates with USB or ISP-supported firmware upgrades. The optional RS485/Modbus communication interface improves process control and data acquisition, enabling remote monitoring and higher operational efficiency in automated liquid filling solutions.

FAQs of 4 Head Liquid Filling Machine Board:

Q: How do I mount the 4 Head Liquid Filling Machine Board in my system?

A: The board supports both panel and DIN rail mounting, allowing you to securely install it in your control cabinet or panel enclosure. Choose the appropriate mounting type depending on the available space and your preferred setup for easy integration with existing industrial automation equipment.

Q: What are the key benefits of using this liquid filling machine board in automation systems?

A: This board provides precise control over four filling heads, supports robust sensor compatibility, offers advanced communication options, and operates reliably over a wide temperature range. It improves productivity, reduces manual intervention, and supports easy firmware upgrades for future enhancements.

Q: When should I consider upgrading the firmware and how is the process carried out?

A: Firmware upgrades should be considered when new features, performance improvements, or bug fixes are released by the manufacturer. The process is straightforward via USB or ISP interfaces, ensuring minimal system downtime and keeping your machines operation up to date.

Q: Where can this board be effectively used?

A: The board is designed for industrial environments, particularly in liquid filling automation systems. It is ideal for use in manufacturing facilities, bottling plants, and other industrial settings requiring precise multi-head liquid dispensing.

Q: What safety and compliance standards does the board meet?

A: This liquid filling machine board adheres to RoHS regulations, features a flame resistance level of UL 94V-0, and offers high insulation resistance exceeding 500 M. These standards ensure safe operation and compliance with industry requirements.

Q: How does the optional RS485/Modbus communication interface benefit industrial users?

A: With RS485/Modbus, users can remotely monitor and control filling operations, enabling seamless integration into industrial networks. This facilitates improved process data acquisition and allows centralized management of the automation system.

Q: What types of sensors are compatible with this PCB?

A: The board is compatible with photoelectric sensors, making it suitable for applications requiring non-contact detection during automatic liquid filling processes.