About 8 Head Liquid Filling Machine Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

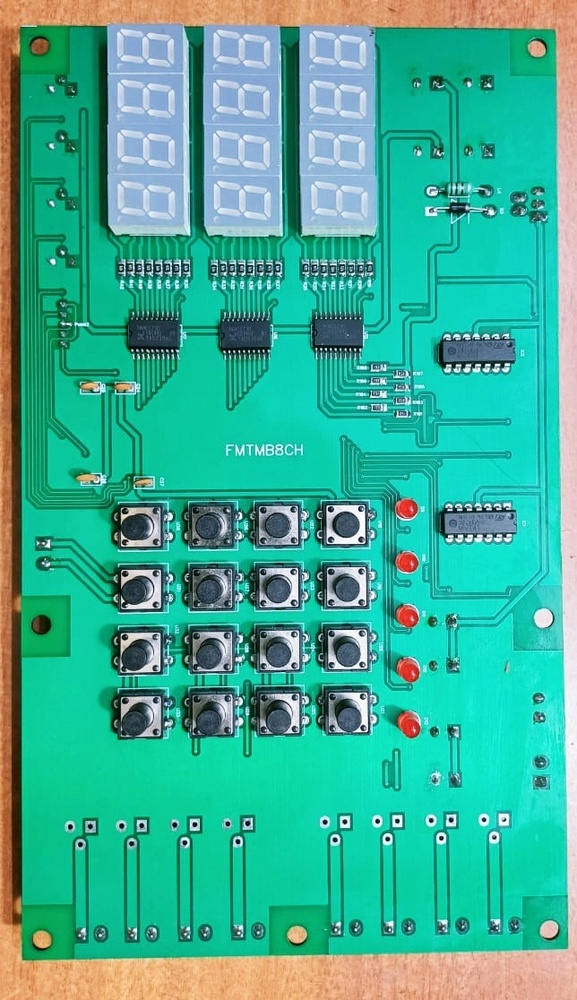

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Superior Signal Processing for Liquid FillingOur 8 Head Liquid Filling Machine Board is engineered to enhance the automation and precision of multi-channel liquid filling systems. With support for eight distinct filling channels, it optimizes productivity in industrial environments where consistent performance and exact dosing are vital. The integrated PLC, relay, and timer circuit ensure swift, reliable switching and signal management.

Robust Construction and ComplianceDesigned with industrial-grade FR-4 epoxy, this rigid PCB guarantees durability and high wear resistance. The panelwith a 1.6 mm thickness and 35m coppermeasures 300 mm x 180 mm. Flame resistance is rated to UL94 V-0 and the board complies with RoHS standards, assuring both safety and environmental responsibility.

Versatile Panel Mounting and ConnectivityInstallation is simplified by panel-mounted design, utilizing screw terminal blocks and pin headers for secure, flexible connections. The board has a white silkscreen for clear labeling and a surface finish of HASL, ensuring reliable soldering and longevity even in demanding production environments.

Reliable Operation Across TemperaturesBuilt for broad operational climates, this control board performs flawlessly between -20C and +70C. Its high insulation resistance (>5x10 ) and voltage endurance (up to 250 V) make it ideal for factories that experience temperature variation, ensuring uninterrupted service and filling accuracy.

FAQs of 8 Head Liquid Filling Machine Board:

Q: How does the 8 Head Liquid Filling Machine Board enhance the filling process?

A: This board efficiently manages and synchronizes eight filling channels, ensuring accurate liquid dispensing and minimizing errors. Advanced components like PLC and photoelectric sensors enable precise signal detection and control for smooth, automated operation.

Q: What is the recommended mounting method for this control board?

A: The board is designed for panel mounting, utilizing secure screw terminal blocks and pin header connectors, making it suitable for integration into machine panels across various automatic liquid filling setups.

Q: When should I consider using this control board in my filling machines?

A: If you require high-precision multi-channel liquid filling with robust automation controlsespecially in environments with temperature fluctuationsthis panel is ideal. Its wide operating range and reliable components support consistent operation under demanding industrial conditions.

Q: Where is this board most commonly applied?

A: It is primarily used in automated liquid filling machines across food, beverage, pharmaceutical, and chemical processing industries where accuracy and speed are crucial.

Q: What process is involved in ensuring this boards quality and compliance?

A: Each board undergoes 100% functional testing to verify performance, and all materials and assemblies conform to RoHS and UL94 V-0 flame resistance standards, ensuring safety, reliability, and environmental compliance.

Q: How can I benefit from customization options for this PCB?

A: OEM and ODM support means you can tailor the boards dimensions, features, and connectivity to match specialized machine designs or unique industry needs, optimizing both machine performance and efficiency.

Q: What are the benefits of its construction and electrical characteristics?

A: The 35m copper thickness, 1.6 mm board, controlled impedance, and high insulation resistance lead to superior durability, low error rates, and minimal signal loss, contributing to long-term, safe, and accurate liquid filling operations.