About 8 Head Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

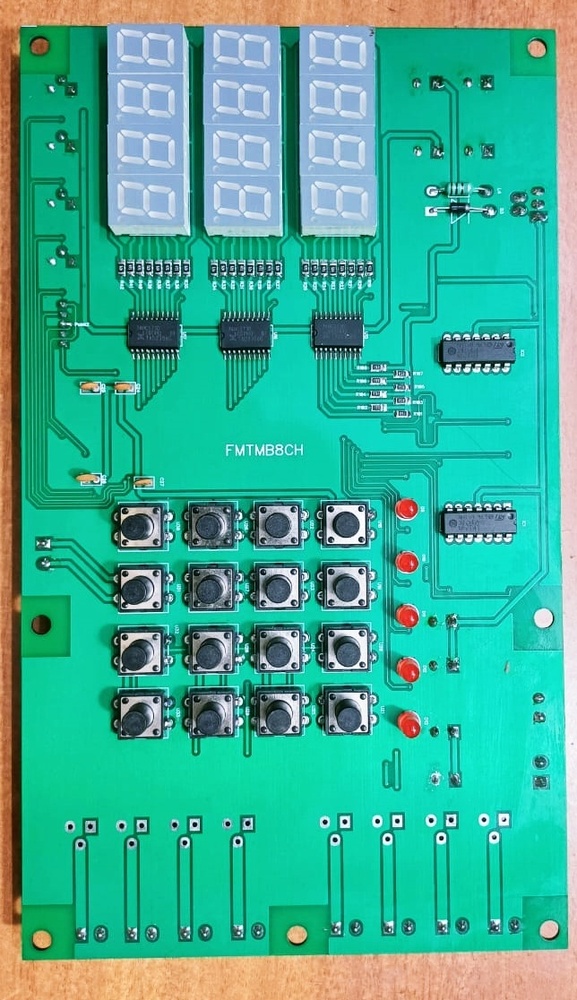

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Reliable Operation Across Industrial EnvironmentsEngineered for stability, the PCB operates in temperatures from -20C to +85C and endures up to 130C, aided by a flame-resistant FR4 epoxy base. This ensures dependable function in demanding industrial liquid filling scenarios, minimizing downtime and improving throughput.

Advanced Electronic Design for Precision ControlEquipped with mixed mounting (Through-Hole & SMD), high-quality ICs, relays, and integrated optical sensor switches, this PCB offers precise control over automated filling machines. Each board features opto-isolated signal inputs and a controlled impedance, reducing interference and maximizing process reliability.

Easy Integration and Flexible ConnectionsWith options for screw terminal and pin header connections, installation is streamlined for both OEMs and service providers. The panel size (300mm x 200mm) and standardized mounting options allow for seamless integration into varied filling machine architectures.

Robust Quality and Environmental ComplianceEach PCB is RoHS compliant and has undergone extensive automated optical inspection (AOI) and electrical (E-test) verification. Optional conformal coating further enhances resistance to environmental factors, extending operational life and maintaining safety standards.

FAQ's of 8 Head Liquid Filling Machine PCB:

Q: How does the 8 Head Liquid Filling Machine PCB ensure reliable operation in harsh industrial environments?

A: The PCB is constructed from flame-resistant FR4 epoxy and operates within a wide temperature range (-20C to +85C), with heat resistance up to 130C. Optional conformal coating and a robust surface finish provide additional protection against moisture, dust, and chemicals, ensuring consistent performance in demanding settings.

Q: What advantages does the mixed mounting type (Through-Hole & SMD) offer for this PCB?

A: Combining Through-Hole and SMD technology allows for greater component flexibility, enhanced mechanical strength, and compact design. This blend supports high-quality components, such as ICs and relays, improving both durability and electrical performance.

Q: When should the optional conformal coating be utilized?

A: Conformal coating is recommended when the PCB will be used in environments with high humidity, chemical exposure, or other harsh conditions. This optional feature adds a protective layer, significantly increasing the board's resistance to contaminants and extending its operational lifespan.

Q: Where can this PCB be used in the liquid filling process?

A: The PCB is engineered for integration into automatic liquid filling machines. It manages precise liquid dispensing and controls multiple nozzles (8 heads) via onboard relays, optical sensors, and quality electronic components, suitable for use in beverage, pharmaceutical, and chemical industries.

Q: What is the process for installing this PCB in a filling machine?

A: The PCB offers flexible mounting and connection options, including screw terminals and pin headers. It is installed in the machine's control panel, where all connectors are attached to the respective inputs and outputs, and power is supplied via 220V AC. Following installation, users should verify operation through functional testing.

Q: How does signal isolation benefit the operation of this PCB?

A: The use of opto-isolators ensures that signals are electrically isolated, protecting sensitive control circuits from noise or voltage surges. This increases reliability and safety, particularly in high-voltage automated machinery environments.

Q: What are the key benefits of choosing this specific PCB for liquid filling applications?

A: Key benefits include high reliability due to quality components and manufacturing checks (100% E-test, AOI), RoHS compliance, versatile mounting options, robust environmental resistance, and precision control via integrated sensors and relays. These features collectively enhance productivity, safety, and reduce maintenance costs.