About 1 head Liquid Filling Machine Circuit

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

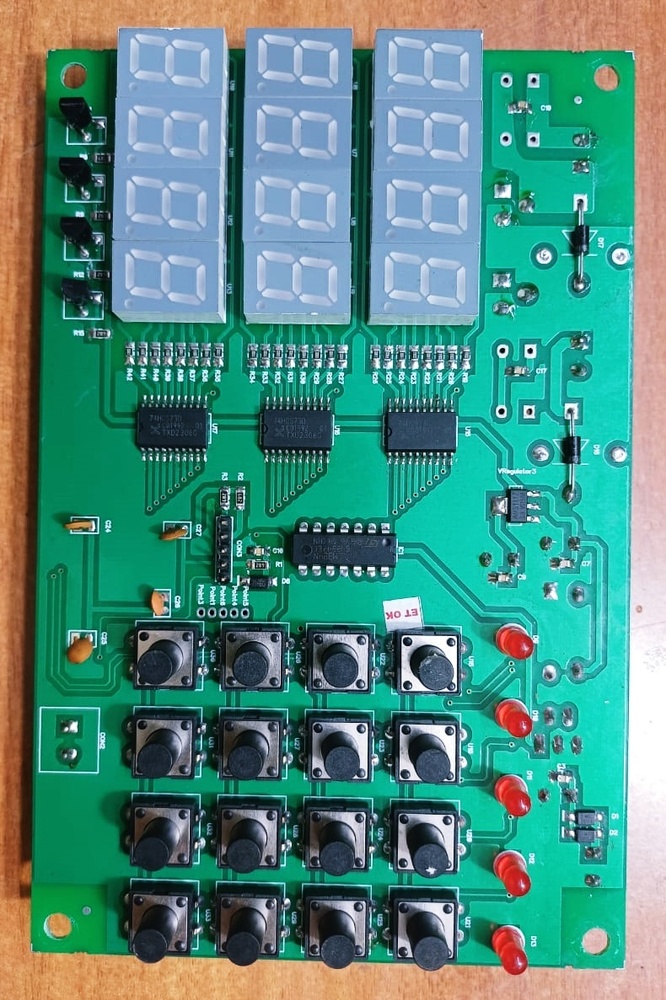

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Versatile and Compact DesignThis single-head filling machine circuit features a compact 100x80 mm FR4 PCB, supporting easy integration into various automatic liquid filling or laboratory dosing systems. Its design accommodates both through-hole and SMD components, making it adaptable for different assembly preferences and service requirements. The inclusion of a terminal block for input/output further simplifies connections.

Reliable Safety and Protection MechanismsThe circuit safeguards operations with a fused input line and snubber circuitry for the relay, protecting against voltage spikes and electrical faults. The board's UL94-V0 flame resistance and insulation exceeding 100 M ensure secure long-term performance, even in demanding industrial environments. HASL finishing enhances soldering quality for dependable operation.

FAQ's of 1 head Liquid Filling Machine Circuit:

Q: How does the 1 Head Liquid Filling Machine Circuit control liquid dispensing?

A: The circuit utilizes time or volume-based integrated logic to control a relay, which in turn operates a pump or solenoid valve. This enables precise control over the amount and timing of liquid being dispensed, supporting both automated filling machines and laboratory dosing systems.

Q: What kind of sensors can be connected to the circuit?

A: The design supports sensor switches such as proximity or level sensors. These sensors provide feedback to the circuit, allowing for automatic initiation or cut-off of liquid filling, thereby enhancing process efficiency and accuracy.

Q: When should the circuit be used in industrial or laboratory applications?

A: This filling circuit is ideal when consistent, automated, and reliable liquid dispensing is required. It serves well in industrial filling lines where precision and repeatability are critical, or in laboratory settings where controlled dosing of fluids is essential.

Q: Where can the circuit be installed for optimal performance?

A: It is engineered for panel mount or cabinet mount installation, offering flexibility for integration into both new and existing machine setups. This ensures safe housing and protection, while maintaining ease of maintenance.

Q: What steps are involved in setting up the circuit for operation?

A: To set up, mount the circuit on the desired panel or cabinet, connect the input power and output relay terminals using the terminal block, interface required sensors, and set the control logic according to the desired fill time or volume. Always ensure fused input protection is in place before operation.

Q: What are the main benefits of using this circuit in your filling applications?

A: The benefits include precise and automated liquid dispensing, enhanced safety with fused and snubber protections, compatibility with common sensors, robust build quality with FR4 and HASL finishing, and compliance with RoHS standards for environmental responsibility.