About 2 Head Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

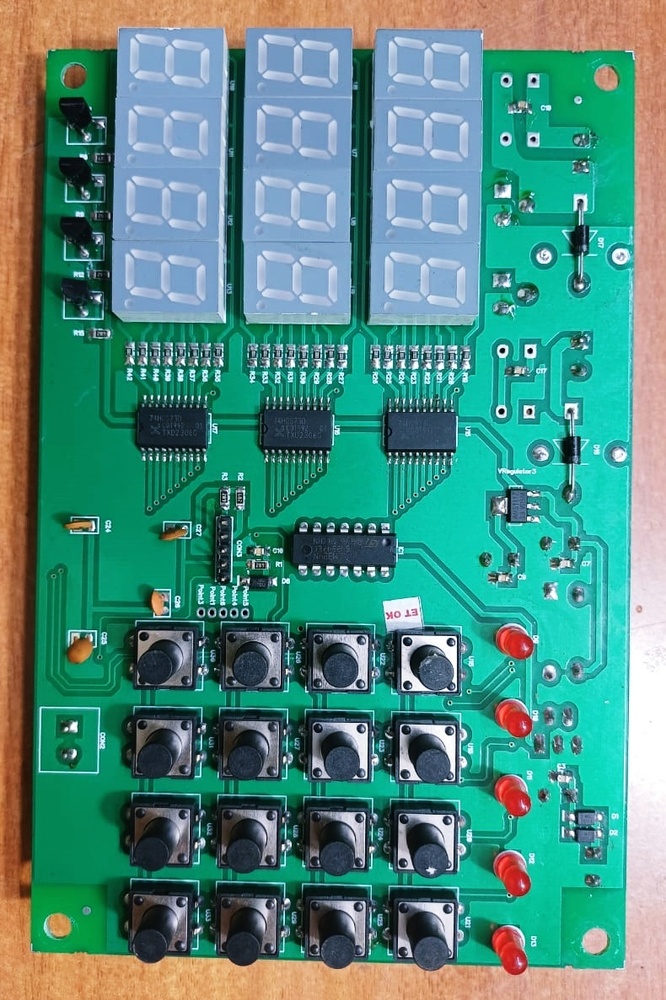

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Precision in Liquid Filling AutomationDesigned for optimal accuracy and reliability, this PCB controls up to two heads for liquid dispensing. Its integrated optical sensors enable real-time monitoring, enhancing fill precision and consistency in each cycle, which is crucial for the stringent requirements of pharmaceutical packaging and other automated filling lines.

Built for Industrial EnvironmentsEngineered to perform under diverse and challenging conditions, this PCB's robust FR4 epoxy glass construction, HAL surface finish, and flame resistance (94V-0) make it ideal for industrial use. Built within a -20C to +70C operating range and 10% to 90% humidity tolerance, it delivers continuous performance in various manufacturing settings.

FAQ's of 2 Head Liquid Filling Machine PCB:

Q: How do I mount the 2 Head Liquid Filling Machine PCB in my equipment?

A: This PCB is designed for panel mounting and comes with pre-drilled holes. Simply align the board within your equipment's designated panel space and secure it using appropriate mounting hardware for a stable installation.

Q: What are the primary applications of this PCB?

A: The board is engineered for use in automatic liquid filling machines and pharmaceutical packaging, providing accurate, automated control of two dispensing heads, and ensuring process consistency and reliability.

Q: When should I update the firmware on this device?

A: Firmware updates should be performed when new features, enhancements, or critical patches are released. The PCB supports on-board programming, making the update process straightforward for maintenance teams or engineers.

Q: Where can I use this PCB?

A: This PCB's environmental tolerance allows installation in most industrial settings across India, handling both temperature extremes (-20C to +70C) and high humidity (10% to 90% non-condensing), suitable for factories, packaging facilities, and automation labs.

Q: What is the process of ensuring board reliability?

A: Each PCB undergoes a comprehensive electrical functionality test and visual inspection after manufacturing. The rigid FR4 base, controlled impedance, HAL surface finish, and compliance with IPC-A-600 Class 2 standards further ensure quality and reliability.

Q: How does the relay output interface work in this board?

A: The two relay output channels are controlled by an onboard microcontroller and relay driver ICs, triggered by optical sensors that detect liquid levels or bottle presence, automating the filling process through electrical switching.

Q: What are the main benefits of using this PCB in my liquid filling machine?

A: Users benefit from high precision, conformity to industry standards, reliability in harsh environments, easy installation, integrated sensors, and straightforward maintenance, which collectively enhance the efficiency of liquid filling operations.