About Inverter PCB Designer

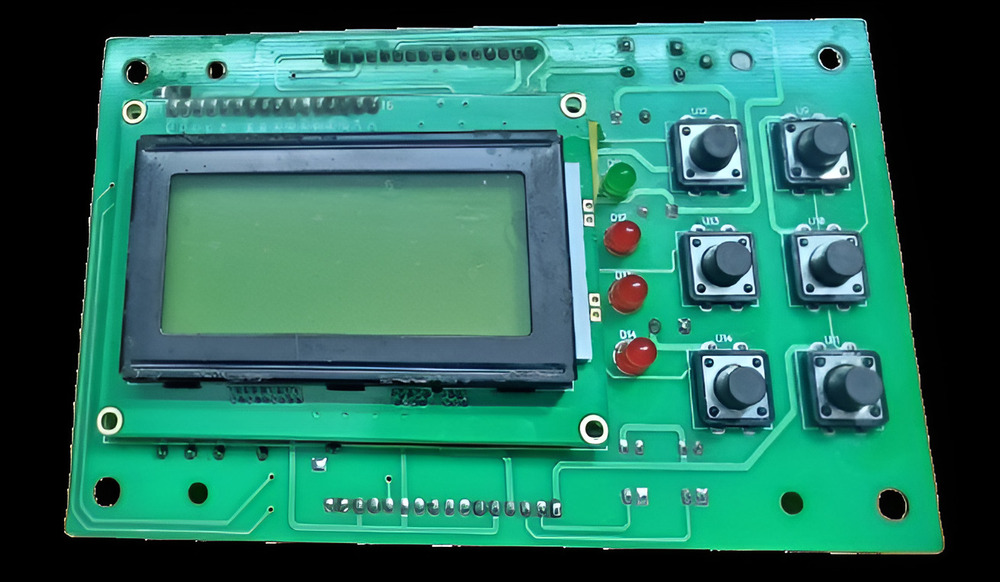

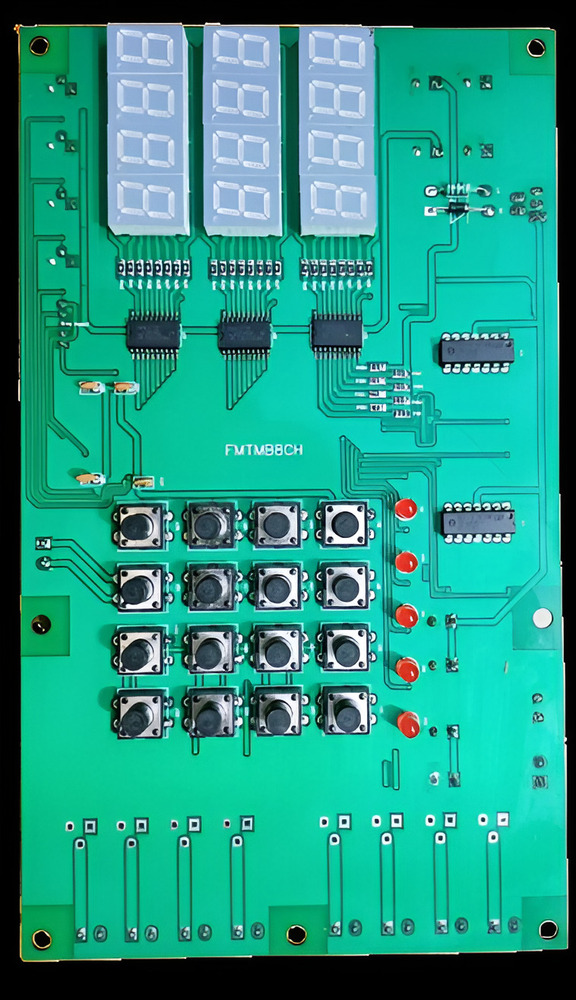

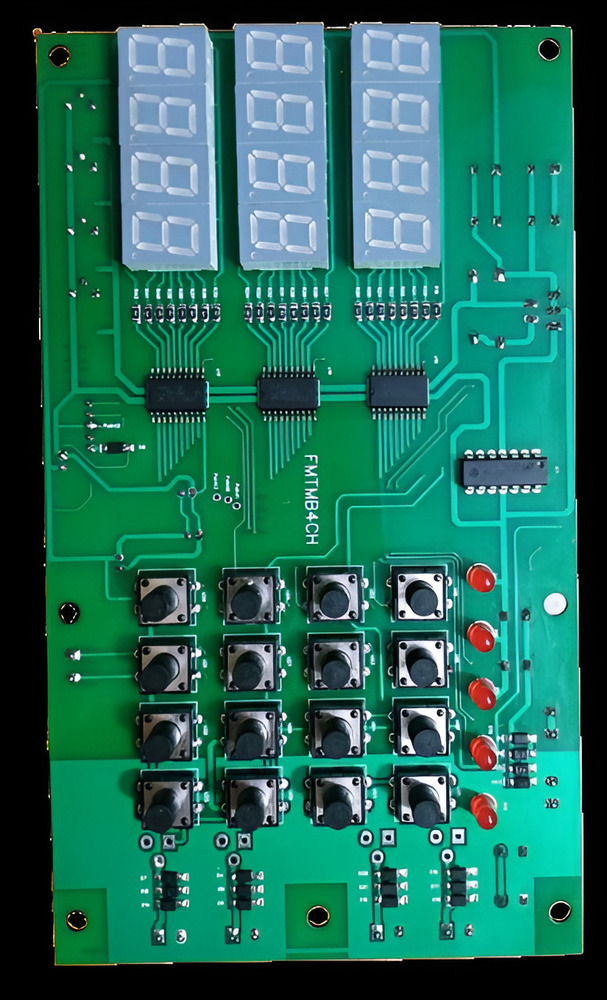

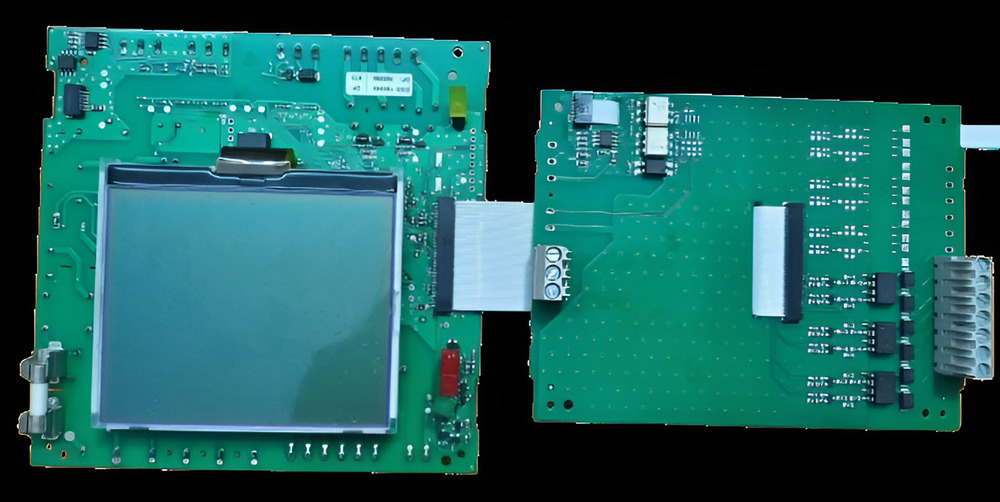

We are having more than 20 years of design experience and are specialize in all kind of Electronics and Embedded circuits designs in Microcontroller, Analog and Digital circuits, Power Systems, AHF Designs, SVG Designs, single Phase and Three Phase UPS and Inverters design, APFC Relays, SCR Switching Boards, IGBT Switching Boards, Motor Control Boards, battery-powered handheld devices, motor drivers and controllers, power systems, boards etc. Our expertise is in electronics circuit design services with a schematic design to final product. This includes selecting relevant electronic components based on the product requirements already present in the product requirements document. Additionally, we elaborate circuit design with actual electronic connections based on functional diagrams.

We do development from concept to final product.

Customized Inverter PCB Design SolutionsBenefit from our expertise in creating custom Inverter PCBs to fit your exact application needs. We accommodate diverse specifications, including board size, double-layer construction, and both through-hole and SMD mountings. With advanced FR4 materials and UL94 V-0 flame retardancy, our designs are built for durability and safety in inverter circuits.

Rigorous Quality and Safety StandardsAll our PCBs undergo a 100% electrical test, meeting stringent insulation (>500M) and fire safety requirements. Certified to the UL94 V-0 standard and RoHS compliant, our products deliver lasting performance while adhering to global safety and eco-friendly regulations, ensuring reliable operation from -20C to +85C.

End-to-End Support and Compatible DesignLeverage our expertise as both manufacturer and service provider in India. Our design files are fully compatible with leading software platforms such as Altium, Eagle, and OrCAD, allowing for a smoother development process and seamless PCB integration into inverter systems.

FAQ's of Inverter PCB Designer:

Q: How can I customize the dimensions of my Inverter PCB?

A: You can specify the required length, width, and mounting type during the design phase, and we will manufacture the PCB according to your exact dimensions and specifications to fit your application needs.

Q: What is the benefit of having UL94 V-0 flame retardant PCBs?

A: UL94 V-0 flame retardant grade ensures that the PCB is highly resistant to catching fire, providing critical safety in high-stress inverter applications where electrical and thermal stresses are frequent.

Q: What testing procedures are used to ensure product reliability?

A: Each Inverter PCB undergoes a 100% electrical test to verify insulation resistance of over 500M, voltage and current capacities, and continuity. This rigorous process guarantees reliable performance in demanding environments.

Q: When should through-hole versus SMD mounting be used in inverter PCB design?

A: Through-hole mounting is optimal for components requiring higher mechanical strength, while SMD is suited for compact designs and automated assembly. We accommodate both types to meet varied design and durability requirements.

Q: Where are these Inverter PCBs manufactured and supplied?

A: Our PCBs are manufactured and supplied directly from our facility in India, serving clients across the country and internationally as a trusted manufacturer, service provider, and supplier.

Q: What design software can I use with your Inverter PCB designs?

A: Our PCBs are fully compatible with major design platforms including Altium, Eagle, and OrCAD, ensuring seamless development and modification of your inverter circuit layouts.

Q: How does RoHS compliance benefit my product development?

A: RoHS compliance guarantees that the PCB contains no hazardous substances, supporting environmentally friendly manufacturing while facilitating regulatory approvals in global markets.