About Liquid Filling Machine PCB

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

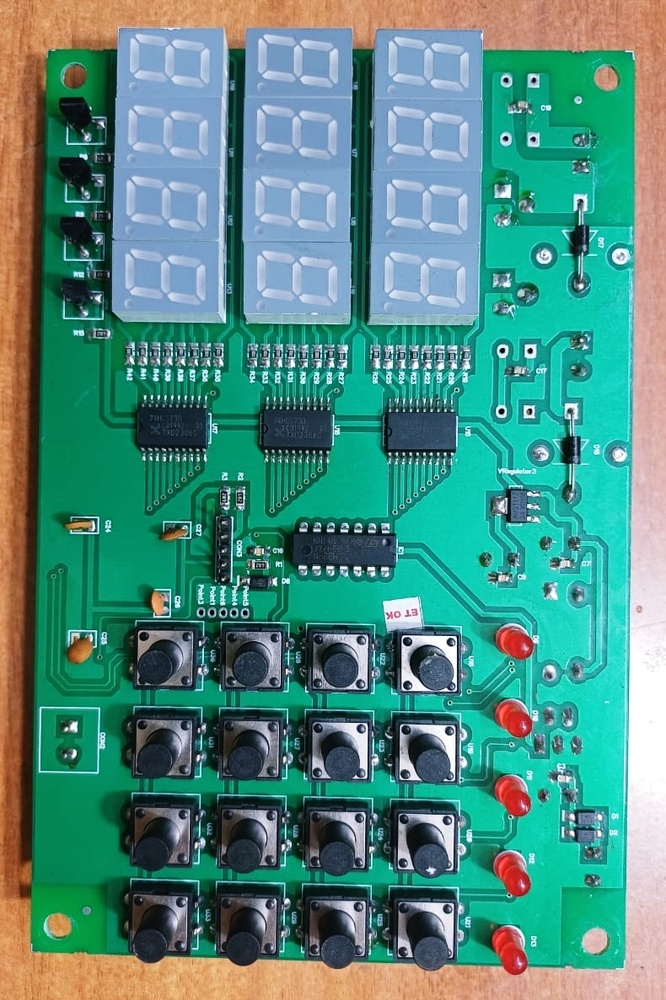

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can customize these machines too as per customer requirement.

Reliable Performance Across Challenging EnvironmentsEngineered for harsh surroundings, this PCB handles temperatures from -20C to +70C, ensuring optimal operation in diverse industrial conditions. Its 1.5kV AC voltage endurance and over 500 M insulation resistance offer exceptional electrical safety, while the green epoxy soldermask and HASL surface finish guard against environmental wear, guaranteeing performance and longevity.

Precision Control and Seamless IntegrationBuilt around advanced microcontroller technology, this PCB features an integrated capacitive sensor switch for accurate liquid dispensing. Compatible with standard ISP headers and panel mounting, it supports straightforward programming, maintenance, and installation. The screw terminal block design ensures secure and reliable connections, making integration into existing setups effortless.

Meeting Stringent Quality and Safety StandardsManufactured to IPC-A-600 Class 2 and UL94 V-0 flame resistance standards, this board ensures reliability and safety. Every unit undergoes 100% E-testing and functional testing, confirming the highest craftsmanship. Durable FR4 base material and high-quality SMD and through-hole components deliver consistent performance for manufacturers and suppliers in India.

FAQ's of Liquid Filling Machine PCB:

Q: How is the Liquid Filling Machine PCB installed in an automatic liquid dispensing system?

A: The PCB is designed for panel mounting and features screw terminal block connectors for secure wiring. It fits in control panels of compatible size (100 mm x 80 mm) and can be integrated directly into existing liquid filling machine setups, thanks to its standard dimensions and mounting features.

Q: What benefits does using a microcontroller-based PCB provide for liquid filling machines?

A: A microcontroller-based PCB allows for precise automation, facilitating accurate control over liquid dispensing cycles. It enables integration with sensor switches and programming interfaces, streamlining operational efficiency, reducing spills, and ensuring consistent output in industrial processes.

Q: When should the PCB be used within its operational temperature range?

A: The PCB is rated for reliable performance between -20C and +70C. It should be operated within this temperature window to ensure optimal functionality, safety, and lifespan, especially in environments with significant temperature fluctuations.

Q: Where is this PCB suitable for use?

A: This PCB is ideal for industrial and commercial liquid filling and dispensing machines. It is suitable for installation in manufacturing facilities, packaging plants, and other environments where automated liquid control is critical.

Q: What is the process for programming the PCB, and what interface does it use?

A: Programming is accomplished through the standard ISP (In-System Programming) header provided on the board. This allows engineers to easily update firmware or adjust control parameters using compatible programming devices.

Q: How does the integrated capacitive sensor switch improve usage?

A: The built-in capacitive sensor switch offers touch-free operation, enhancing hygiene, reducing mechanical wear, and providing rapid response for monitoring liquid levels. This feature streamlines user interaction and boosts overall system productivity.

Q: What safety and quality standards does this PCB meet?

A: The board is manufactured to IPC-A-600 Class 2 standards, features a UL94 V-0 flame-resistant rating, and undergoes 100% E-testing and functional testing. This guarantees high electrical, mechanical, and fire safety for industrial operations.