About Weight Based Liquid Filling Machine Circuit Board

We are manufacturer of Made In India Semi Automatic Heavy Duty High Torque Low and Medium Viscous Digital Liquid Filling Machine in 2 head, 4 head 8 head and 12 head in time base and weight sensor based.

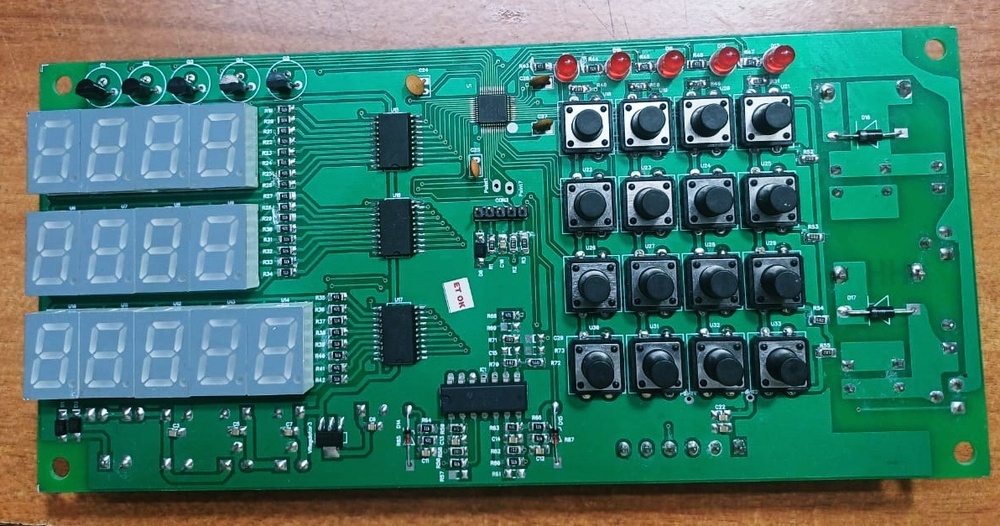

Precise Liquid Filling: This semi-automatic machine allows for accurate filling of liquids with digital displays for filling time, waiting time, and counter.

User-Friendly Controls: Features a simple keypad with numeric buttons and function keys like CPU, Volume, Mode, Setting, and Timing for easy operation.

Efficient Operation: The intelligent 32bit MCU design streamlines the liquid filling process, ensuring consistent and reliable performance.

Versatile Application: Suitable for filling a wide range of liquid products in various industries, such as food, pharmaceuticals, and cosmetics.

We can cutomize these machines too as per customer requirement.

For any further clarification of modification, Please call or WhatsApp us on 8805013960 / 8010527998.

Advanced Control InterfaceThe circuit board is engineered with Start/Stop, Tare, and Calibrate controls, ensuring precise management of the liquid filling process. Its digital I/O ports enable seamless integration with a variety of sensors and actuators, supporting up to 8 connections. Panel mounting holes and robust relay outputs (24V/5A) make this solution suitable for demanding industrial environments.

Display and Sensor CompatibilityDesigned for operational clarity, the board provides support for both 7-segment LED and LCD displays, offering flexible readout options. Integrated with proximity and weight sensor interfaces, it guarantees accurate and responsive measurements. This compatibility ensures smooth interaction with various weighing and liquid handling equipment in manufacturing settings.

FAQ's of Weight Based Liquid Filling Machine Circuit Board:

Q: How is the circuit board for the weight based liquid filling machine installed?

A: The board features dedicated panel mounting holes, allowing it to be securely fixed to enclosures or machine panels using standard hardware. Detailed installation instructions are provided for seamless integration with existing setups.

Q: What display options are supported by this PCB assembly?

A: The circuit board supports both 7-segment LED displays and LCD displays, offering users flexibility in how filling parameters and weights are monitored.

Q: When should I perform firmware upgrades and how are they done?

A: Firmware is pre-programmed and can be upgraded via In-System Programming (ISP) as needed. Upgrades are recommended when new features or enhancements are released by the manufacturer to ensure optimal performance.

Q: Where can this circuit board be used?

A: Ideal for use in industrial filling machines, the board suits manufacturing, packaging, and processing facilities requiring precise weight-based liquid filling. Its 0C to 60C operating range and robust construction make it suitable for various operational environments across India.

Q: What is the process for calibrating the weight sensors using this board?

A: Calibration is straightforward via the on-board control interface, which includes a dedicated 'Calibrate' button. The process involves placing known weights and following step-by-step prompts on the display for accurate calibration.

Q: How does the combination of Through-Hole and SMD assembly benefit the user?

A: Blending Through-Hole and Surface Mount Devices (SMD) allows for optimized space, durable solder joints, and ease of servicing. Critical components benefit from mechanical strength while sensitive parts can be reliably mounted for performance.